المكونات الأساسية لمبادئ تصميم غرفة التبريد

السلامة الهيكلية في الهياكل الفولاذية المسبقة الصنع

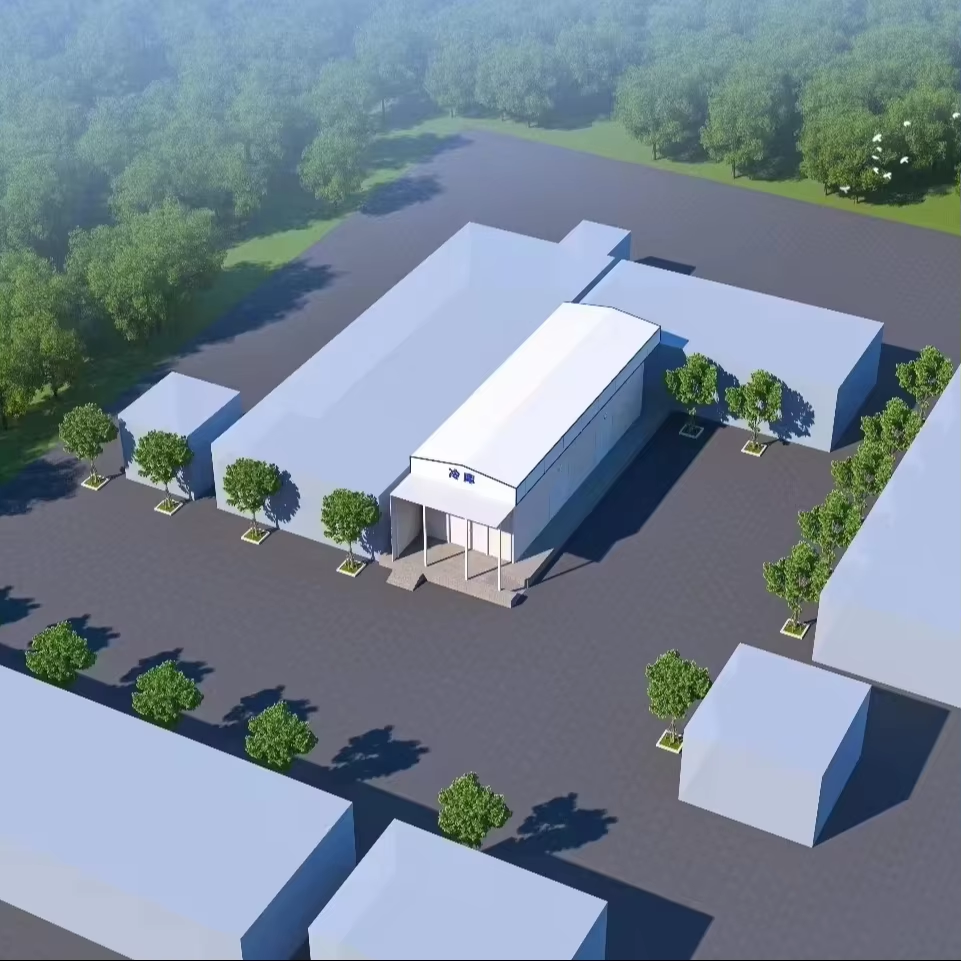

يُعد الحفاظ على البنية الهيكلية للغرف الباردة أمراً في غاية الأهمية، خاصة في منشآت تخزين الأغذية حيث التحكم في درجة الحرارة هو كل شيء. إن استخدام مواد ذات جودة عالية تحدث فرقاً كبيراً في هذا المجال. اكتسبت المباني الفولاذية الجاهزة شعبية كبيرة في استخدامها لمخازن التبريد، لأنها قادرة على تحمل درجات الحرارة القاسية دون أن تتدهور مع مرور الوقت. هذه المنشآت تدوم لفترة أطول مقارنة بمعظم البدائل الأخرى، حيث لا يتأثر الفولاذ فيها بالانحناء أو التدهور كما هو الحال في مواد أخرى. عند قيام المصانع بتجميع هذه الوحدات الجاهزة، يتم إنشاء وصلات قوية بين المكونات المختلفة، إلى جانب تضمين دعامات فولاذية في الإطار كاملاً. يساعد هذا التعزيز في مقاومة الأضرار الناتجة عن تراكم الرطوبة، والاهتزازات الناتجة عن وحدات التبريد، بل وحتى الزلازل الخفيفة في بعض المناطق. سيُخبرك معظم مديري المنشآت أن الاستثمار في بناء عالي الجودة في البداية يوفّر المال على المدى الطويل فيما يتعلق بالإصلاحات والصيانة.

يتطلب النظر في هذه الهياكل الانتباه إلى بعض عناصر التصميم التي تساعد فعليًا في تجميعها بشكل أفضل. تضيف الدعامات الفولاذية استقرارًا إضافيًا للمباني، وتلك الأجزاء المتشابكة تساعد حقًا في الحفاظ على تجميع كل شيء بشكل صحيح. الالتزام بمعايير مثل ISO 9001 أو الحصول على شهادة من منظمات موثوقة يعني أن العمل يجتاز الاختبارات الأساسية المتعلقة بالسلامة لمعظم الصناعات. إن اتباع هذه الإرشادات لا يفعل أكثر من مجرد الوفاء بالحد الأدنى من المتطلبات، بل يمنح العملاء راحة البال اللازمة مع العلم بأن ما يرونه أمامهم مُبنى ليصمد أمام التآكل الطبيعي مع مرور الوقت.

تقنيات منع الجسور الحرارية

عندما يحدث الجسر الحراري في مرافق التخزين البارد، فإنه يسمح بمرور الحرارة عبر الأجزاء الإنشائية مما يضر بالكفاءة الطاقية العامة. ومنع حدوث ذلك يساعد في الحفاظ على درجات الحرارة المناسبة داخل المنشأة ويقلل من استهلاك الطاقة. هناك عدة طرق للتعامل مع هذه المشكلة، منها إضافة فواصل حرارية بين المواد والعزل المناسب للمناطق المعرّضة للخطر. يلجأ مشغلو الغرف الباردة في كثير من الأحيان إلى استخدام ألواح البولي يوريثين لجدرانهم نظرًا لخصائصها العازلة الممتازة. توفر هذه الألواح حواجز ضد حركة الحرارة، مما يجعلها خيارًا شائعًا لدى المرافق التي تسعى لتحسين أدائها الطاقي دون إجراء تغييرات إنشائية كبيرة.

تشير العديد من الدراسات إلى مدى فعالية هذه الأساليب في الممارسة العملية. يمكن أن تؤدي الفواصل الحرارية عند تركيبها بشكل صحيح إلى تقليل تكاليف الطاقة بنسبة تصل إلى 20 بالمائة وفقًا للنتائج الحديثة، مما يجعلها إضافات ذات قيمة كبيرة لأي نظام. وفيما يتعلق بثبات درجات الحرارة داخل غرف التبريد، فإن العزل الجيد يلعب دورًا كبيرًا أيضًا. تعمل الألواح المصنوعة من مواد عازلة عالية الجودة على الحفاظ على ظروف ثابتة في جميع أنحاء مناطق التخزين. ولأي شخص يرغب في تحسين كفاءة التخزين البارد، فإن التعرف على هذه الأساليب لا يفيد فقط، بل يكاد يكون ضروريًا إذا أراد توفير المال على فواتير الكهرباء دون التأثير على جودة المنتج.

استراتيجيات عزل متقدمة لتحكم في درجة الحرارة

مقارنة بين البولي يوريثين والألواح العازلة لمخازن البرودة

عند النظر في مواد العزل المختلفة لمناطق التخزين الباردة، فإن المقارنة بين ألواح البولي يوريثين وبدائلها الأخرى تعتبر خطوة مهمة قبل اتخاذ أي قرارات. تتميز هذه الألواح حقاً بقدرتها على منع تسرب الحرارة، مما يحافظ على استقرار درجات الحرارة حتى في الظروف القاسية. يجد العديد من أصحاب الأعمال أنها استثمار مربح على المدى الطويل نظراً لتوفيرها المال بمرور الوقت. كما أن هناك مواد عازلة أخرى قد تكون خيارات جيدة أيضاً، خاصة إذا كانت سهولة التركيب عاملاً مهماً. فوزنها الخفيف يجعل تركيب هذه الألواح أسرع، مما يقلل من تكاليف العمالة ويحد من التأخير في الإنتاج خلال مرحلة التركيب. يشير الخبراء في الصناعة بشكل منتظم إلى البولي يوريثين باعتباره الخيار الأفضل من حيث كفاءة العزل، مشيرين إلى أن المنشآت التي تستخدم هذا النوع من المواد تلاحظ عادةً انخفاضاً ملحوظاً في فواتير الطاقة الشهرية بعد التركيب.

طرق دمج حاجز البخار

تعتبر الحواجز البخارية ضرورية للحفاظ على استقرار درجات الحرارة في تصميمات الغرف الباردة، لأنها تمنع تراكم الرطوبة داخل الجدران والأسقف. بدون هذه الحواجز، نرى غالبًا ظهور مشاكل العفن إلى جانب هدر في تكاليف الطاقة. عندما يلامس الهواء الخارجي الدافئ تلك الأسطح الداخلية الباردة في غرف التخزين، فإن التكاثف يحدث بشكل طبيعي ما لم يكن هناك شيء يمنعه. هذا هو السبب في أن البنائين المهرة يخططون مسبقًا لتضمين الحواجز البخارية أثناء مراحل البناء. يجب أن يتم تركيب هذه الحواجز بعناية في الأماكن التي تحدث فيها التغيرات الحرارية بشكل متكرر، ويجب اختيار مواد تتناسب جيدًا مع العزل الموجود. عادةً يوصي الخبراء في المجال بوضع الحواجز مباشرة بين طبقات العزل المختلفة أو استخدام أوراق البولي إيثيلين للحصول على أفضل النتائج. أظهرت الأبحاث أيضًا أن التركيب الجيد للحواجز البخارية يمكن أن يحدث فرقًا كبيرًا. تشير بعض الدراسات إلى تقليل بنسبة تصل إلى 40% في مشاكل العفن بعد التركيب السليم، مما يعني أداءً أفضل بشكل عام وظروفًا أكثر نظافة لتخزين البضائع. يجد معظم مشغلي مخازن التبريد أن الاستثمار في حواجز بخارية عالية الجودة يعود عليهم بفوائد من خلال تقليل متاعب الصيانة وزيادة عمر المعدات.

تكوين الأنظمة الميكانيكية

معايير اختيار وحدة التكثيف الصناعية

يُحدث اختيار الوحدة الصناعية للتبريد الفرق عندما يتعلق الأمر بأداء التبريد الجيد مع الحفاظ على فواتير الطاقة منخفضة. هناك عدة عوامل يجب مراعاتها قبل اتخاذ قرار الشراء. أولاً، يجب مطابقة سعة الوحدة لاحتياجات المنشأة الفعلية، فهذا يمنع حدوث مشاكل مثل عدم قدرة النظام على التبريد أو هدر الطاقة بسبب تشغيله بجهد زائد. كما أن الكفاءة في استخدام الطاقة مهمة أيضًا. تميل الوحدات ذات التصنيفات الأعلى في الكفاءة إلى توفير المال على المدى الطويل ومساعدة الشركات في تحقيق أهدافها البيئية. أصبحت الاعتبارات البيئية مهمة للغاية في الوقت الحالي بسبب القوانين المتعلقة بإصدار الغازات الدفيئة. عادةً ما لا تتوافق مواد التبريد المستخدمة في الأنظمة القديمة مع المعايير الحالية، لذا التحقق من نوع مادة التبريد التي تستخدمها الوحدة قبل الشراء يمكن أن يوفّر متاعب مستقبلية.

يُحدث نوع الغاز المبرد المستخدم فرقًا كبيرًا في مدى كفاءة النظام في تبريد الأشياء وفيما إذا كان يتوافق مع تلك التنظيمات التي تلوح في أفق الصناعة. هناك بعض الخيارات التي تكون ببساطة أكثر كفاءة من حيث استهلاك الطاقة، وعادة ما تكون أيضًا أكثر صداقة للبيئة. خذ على سبيل المثال المواد الطبيعية مثل ثاني أكسيد الكربون أو الأمونيا، فلقد اكتسبت هذه المواد زخمًا مؤخرًا لأنها لا تسهم بشكل كبير في الاحتباس الحراري. إن اختيار نوع معين من بين مختلف الغازات المبردة يؤثر على قدرة الشركات على البقاء في حدود الإطار القانوني الذي وضعته اتفاقيات مثل بروتوكول كيوتو، كما يساعد أيضًا في حماية الاستثمارات عندما تظهر قواعد جديدة. تُظهر الدراسات والتجارب العملية مدى أهمية هذا الاختيار. هناك العديد من الأمثلة التي توضح كيف قام بعض الأعمال التجارية بتبني بدائل أكثر صداقة للبيئة، وحققت في المقابل انخفاضًا في معدلات الانبعاثات، إلى جانب تقليل حقيقي في التكاليف التشغيلية اليومية، وهو أمر يتناسب تمامًا مع الأهداف البيئية التي تسعى معظم الدول لتحقيقها.

تحسين دوائر التبريد

الحصول على فهم جيد لكيفية عمل دوائر التبريد وضمان تحسينها يُحدث فرقاً كبيراً عندما يتعلق الأمر بتشغيل نظام تبريد بكفاءة. تتكون هذه الدوائر أساساً من عدة أجزاء رئيسية تشمل الضواغط (الكومبروسورات)، والمكثفات، ومبخرات، والصمامات التمددية الصغيرة التي غالبًا ما نهملها. ولكل مكون دور خاص به في الحفاظ على البرودة طوال العملية بأكملها. وعندما يعمل كل شيء معاً بشكل صحيح، فهذا ما يحدد ما إذا كان النظام يعمل بكفاءة أم لا. вот لماذا يُعد إعداد النظام بشكل صحيح أمراً بالغ الأهمية بالنسبة للأداء. إذ إن الدائرة التي تم تهيئتها بشكل غير صحيح يمكن أن تؤدي إلى هدر الطاقة وزيادة تكاليف التشغيل على المدى الطويل.

يبدأ استخلاص أقصى استفادة من الأنظمة بتحديد الأحجام المناسبة للمكونات ودمج تحكم ذكي. عندما تكون الأجزاء ذات الأحجام الملائمة لمهامها، فإنها تعمل بشكل أفضل دون هدر للطاقة أو التعرض لعطل مبكر. تأخذ التقنيات الحديثة في مجال التحكم خطوة إضافية إلى الأمام، حيث تقوم بإجراء تعديلات فورية بناءً على ما يحدث فعليًا داخل النظام في أي لحظة معينة، مما يقلل من هدر الطاقة بشكل عام. عند النظر فيما يحدث في الميدان، نجد أدلة واضحة على أن الدوائر المحسّنة تحقق نتائج فعلية. تشير بعض الدراسات إلى ارتفاع في الكفاءة بنسبة تصل إلى 30% عندما يعمل كل شيء معًا بشكل منسق. ولا تقتصر هذه التحسينات على الفوائد المالية فحسب، بل تُظهر الشركات التي تطبّق هذه الأساليب عادةً تكاليف تشغيل أقل مع تقليل بصمتها البيئية الكلية، وهو أمرٌ يكتسب أهمية متزايدة في ظل الضغوط المتزايدة على الصناعات للعمل بشكل مستدام.

تنفيذ هيكل حديدي مستدام

تقنيات الإطار الموفرة للطاقة

عند بناء مرافق التخزين البارد، تلعب طرق الإطارات الموفرة للطاقة دوراً كبيراً في الحفاظ على درجات الحرارة منخفضة مع تقليل فواتير الطاقة. تعتمد معظم غرف التبريد الحديثة بشكل كبير على ألواح عازلة تمنع تسرب الحرارة من الداخل أو الخارج. هذه الألواح ليست عادية على الإطلاق - ففي كثير من الأحيان تحتوي على رغوة البولي يوريثين محصورة بين طبقات معدنية، تعمل كغطاء سميك للغاية للمبنى. كما أصبحت إطارات الفولاذ نفسها أكثر ذكاءً أيضاً. إن البناء المسبق الجاهز يعني ارتكاب أخطاء أقل أثناء التركيب وتقليل الهدر في المواد. خذ على سبيل المثال المستودع الكبير في كانساس سيتي. لقد قاموا بتحديث منشأتهم بالكامل بأنظمة جديدة العام الماضي، وشاهدوا انخفاضاً في فاتورة الكهرباء الشهرية بنسبة تصل إلى ربع القيمة. هذا النوع من التوفير يتراكم بسرعة عندما نتحدث عن عمليات على نطاق صناعي تعمل على مدار الساعة طوال أيام الأسبوع.

تكامل المواد القابلة لإعادة التدوير

يحدث استخدام المواد القابلة لإعادة التدوير في بناء غرف التبريد فرقاً حقيقياً لعالمنا. عندما يختار المقاولون مواداً مثل الألومنيوم أو أنواع معينة من الصلب يمكن إعادة تدويرها مراراً وتكراراً، فإن ذلك يقلل من الضرر البيئي ويحافظ على فعالية هذه المواد لفترة أطول. الغرف الباردة التي تُبنى بهذه الطريقة تحتفظ بنفس القوة الهيكلية، كما قد توفر في الواقع المال على المدى الطويل. على سبيل المثال، يشير تقرير الجمعية العالمية للصلب إلى انخفاض بنسبة تصل إلى النصف في الانبعاثات الكربونية عند استخدام الصلب المعاد تدويره مقارنةً بالبناء بالصلب التقليدي. وبالطبع، فإن تقليل البصمة الكربونية في مواقع البناء المختلفة أصبح أمراً بالغ الأهمية في الوقت الحالي. والآن تنظر المزيد من الشركات إلى مبانيها نظرة خضراء، تحاول الالتزام بمعايير البيئة الدولية دون تكبد تكاليف باهظة.

تعزيز الكفاءة التشغيلية

تصاميم قابلة للتوسع لتحقيق المرونة

تُعد غرف التبريد التي تُبنى بتصميم وحدوي (مودولاري) مصدرًا للفوائد الحقيقية عندما يتعلق الأمر بتوسيع العمليات والتكيف مع مرور الوقت. إن التصميمات التقليدية تكون صلبة إلى حد كبير بمجرد تركيبها، لكن الأنظمة الوحدوية تتيح للشركات القدرة على النمو أو تغيير التكوين دون عناء كبير. فخذ على سبيل المثال مصانع معالجة الأغذية، حيث تبدأ العديد منها بحلول تخزين أساسية ثم تضيف وحدات إضافية مع زيادة الإنتاج. عادةً ما تعتمد هذه التصاميم على مكونات مسبقة الصنع من الصلب تُثبت بسرعة، مما يجعل التعديلات أمراً سهلاً. ومن الجدير بالذكر أن الشركات التي تتحول إلى هذا النهج تلاحظ عادةً تحسنًا بنسبة 20٪ في الكفاءة وفقًا للتقارير الصناعية، وذلك لأنها تُنفق وقتًا ومالًا أقل في إعادة ترتيب المساحات عندما تتغير الاحتياجات.

بروتوكولات الصيانة الوقائية

تحتاج غرف التبريد إلى ممارسات صيانة وقائية جيدة لضمان تشغيلها بسلاسة. عندما تقوم الشركات بإصلاح المشكلات الصغيرة قبل أن تتحول إلى مشكلات كبيرة، فإن الجميع يوفر المال ويحافظ على استمرارية العمليات دون انقطاع. تعني خطة الصيانة القوية إنشاء فحوصات دورية، والنظر بدقة إلى جميع المعدات، والتأكد من أن الموظفين يعرفون ما يجب القيام به عند الحاجة إلى إصلاح الأعطال. يوضح مثال واقعي ما يحدث عندما تأخذ الشركات روتين الصيانة على محمل الجد. بعد تطبيق بروتوكولات صيانة صارمة، تقلصت فترات التوقف لدى شركة لتخزين الأغذية بنسبة 30 بالمئة تقريبًا، وانخفضت تكاليف الإصلاح السنوية بنسبة 15 بالمئة. أرقام مثل هذه توضح سبب اعتبار العديد من المشغلين الأذكياء اليوم للصيانة جزءًا من استراتيجيتهم لتحقيق الأرباح، وليس مجرد مهمة مملة.