المكونات الهيكلية لغرف التبريد الخاصة بزراعة الفطر

مزايا الإطارات الفولاذية المُسبقة الصنع

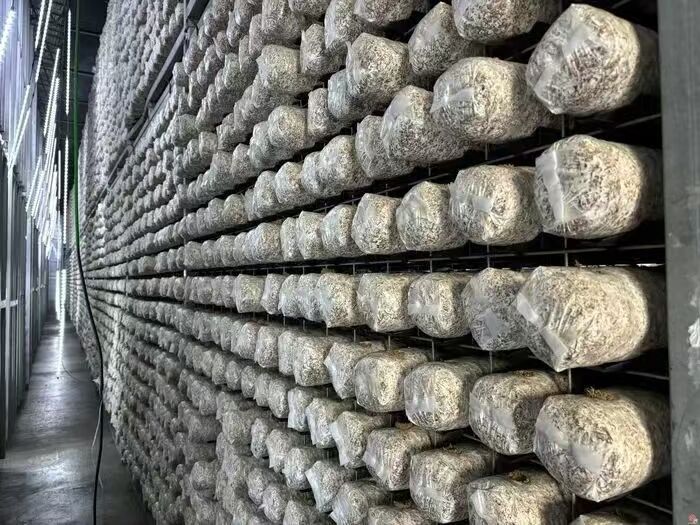

تُعدُّ هياكل الإطارات الفولاذية التي تُصْنَع مسبقًا خارج الموقع مصدرًا للعديد من الفوائد عند بناء غرف التبريد لمزارع الفطر. فهي تُجمَّع بسرعة كبيرة، مما يقلل من مدة الإنشاء ويتيح الانتهاء من المشاريع قبل الموعد المحدد. والتركيب السريع يعني تقليل المشاكل الناتجة عن التأخير، بحيث يُمكن البدء فورًا في تشغيل منطقة التبريد والتخزين الخاصة بالفطر دون إضاعة الوقت الثمين. كما أن هذه الإطارات المعدنية تدوم لفترة أطول بكثير من مواد البناء التقليدية التي نراها في كل مكان. وبما أنها تتحمل الاستخدام لفترة أطول، فإن الحاجة إلى عمليات الإصلاح تقل مع مرور الوقت، مما يوفّر المال على المدى الطويل لأي شخص يرغب في إدارة العمليات بشكل مستدام. وبالإضافة إلى ذلك، فإن تصميم هذه الهياكل يمنح المزارعين قدرًا كبيرًا من المرونة لتخصيص المساحات وفقًا لاحتياجاتهم الخاصة لزراعة أنواع مختلفة من الفطر بشكل صحيح. فقط انظر إلى عدد المزارع التي طبّقت هذه الأنظمة لإنشاء بيئات مثالية يزدهر فيها الفطر ويظل على جودته العالية.

مقاومة التآكل في الفولاذ المجلفن

يتميز الصلب المجلفن بأنه يقاوم التآكل بشكل كبير، مما يجعله مناسبًا جدًا للغرف الباردة التي تحتوي فيها الهواء على الكثير من الرطوبة. يمنع طبقة الزنك الموجودة على السطح تشكّل الصدأ، وهو أمر مهم جدًا عندما تتعرض الهياكل باستمرار لظروف رطبة. تؤكد الأبحاث هذا أيضًا، حيث أظهرت العديد من الاختبارات الميدانية أن الصلب المجلفن يستمر تقريبًا ضعف مدة استمرار الصلب العادي قبل الحاجة إلى استبداله. هذا يعني أن الحاجة إلى إصلاح الأجزاء أو استبدالها تقل بمرور الوقت، مما يؤدي إلى خفض تكاليف الصيانة. يجد مربو الفطر الذين يغيرون هيكل تخزينهم البارد ليكون من الصلب المجلفن أن الاستثمار يحقق قيمة أفضل. فهذه المواد تتحمل التغيرات المستمرة في درجات الحرارة والتقلبات في الرطوبة الناتجة عن تخزين الفطر بشكل صحيح، وتكوّن بيئة أكثر موثوقية لحفظ جودة المحصول دون إنفاق الكثير على الإصلاحات.

كفاءة عوازل الألواح البولي يوريثين

يعتمد مزارعو الفطر بشكل كبير على ألواح البولي يوريثان لتلبية احتياجاتهم من التخزين البارد نظرًا لقدرتها العالية على الحفاظ على استقرار درجات الحرارة. تتميز هذه الألواح أيضًا بخصائص عزل حراري ملحوظة، حيث توفر قيمة عزل تقدر بـ R-value تبلغ حوالي 6.5 لكل بوصة من السمك. وهذا يعني تنظيمًا أفضل لدرجة الحرارة داخل غرف التبريد حيث يحتاج الفطر إلى النمو بشكل صحيح. عندما لا تتسرب الحرارة بسهولة، يلاحظ المشغلون وفرًا حقيقيًا في تكاليف الكهرباء. وقد أفاد بعض مديري المرافق بخفض فواتير الطاقة لديهم بنسبة تصل إلى 30٪ بعد الانتقال إلى هذا النوع من الألواح. وبالإضافة إلى توفير المال، تساعد هذه الألواح في خلق بيئة ثابتة يريدها الفطر. تبقى التقلبات الحرارية عند الحد الأدنى، مما يحافظ على سلامة الفطريات الدقيقة لفترة أطول دون أن تفسد مبكرًا.

أنظمة تنظيم درجة الحرارة

وحدات التكثيف ذات التبريد الهوائي - شرح

تعمل وحدات التكثيف المبردة بالهواء بشكل ممتاز في إخراج الحرارة من أنظمة التبريد، مما يجعلها مثالية للتطبيقات التي تتطلب تخزينًا باردًا. تعتمد طريقة عمل هذه الوحدات على الهواء المحيط بدلاً من الماء لأغراض التبريد، وهو أمر يكتسب أهمية كبيرة في المناطق التي تعاني من ندرة المياه أو التي تخضع لقيود صارمة في الحفاظ عليها. كما أن متطلبات الصيانة تكون عادةً أقل مقارنةً بالبدائل التقليدية المبردة بالماء، وذلك لأنها لا تحتوي على شبكة معقدة من الأنابيب تحتاج إلى مراقبة مستمرة. من الناحية الاقتصادية، يجد العديد من الشركات أن هذه الأنظمة توفر المال على المدى الطويل نظرًا لعدم وجود تكاليف متكررة للمياه أثناء التشغيل. وبالإضافة إلى توفير التكاليف المالية فقط، فإن انخفاض استهلاك المياه يعني تقليل الضغط الواقع على الموارد المحلية، مما يسهم بشكل إيجابي في تحقيق الأهداف المتعلقة بالاستدامة دون التأثير على معايير الأداء.

مواصفات التبريد التجاري

بالنسبة لأنظمة التبريد التجارية المستخدمة في الغرف الباردة، فإن الالتزام بمعايير أداء معينة أمر لا غنى عنه إذا أردنا التحكم السليم في درجة الحرارة. وعندما يتعلق الأمر بتخزين الفطر على وجه التحديد، تصبح عوامل مثل استهلاك الطاقة وقدرة النظام مهمة جدًا لأن الأنواع المختلفة تحتاج إلى ظروف مختلفة. فالفطر كائنات حساسة في النهاية. ومعظم الوحدات التجارية هذه الأيام مصممة للعمل باستمرار دون توقف، مما يجعلها مناسبة للمتطلبات الصارمة لعمليات الأعمال حيث لا يمكن التساهل مع توقف النظام. إن اتباع الإرشادات الصادرة عن منظمات مثل ASHRAE يساعد عند اختيار معدات تبريد عالية الجودة. وتوجهنا هذه المعايير نحو أنظمة تعمل بالفعل بكفاءة لتلبية احتياجات المزارعين فيما يتعلق بزراعة الفطر وتخزينه بشكل سليم.

القدرة على التحكم في المناخ متعدد المناطق

تتيح أنظمة التحكم في المناخ التي تدير مناطق متعددة للمشغلين ضبط مستويات الحرارة والرطوبة بشكل منفصل عبر مختلف المناطق داخل مرافق التخزين البارد. بالنسبة لمزارعي الفطر، تُحدث هذه التكنولوجيا فرقاً كبيراً في إنشاء ظروف مثالية لأنواع مختلفة من الفطر مثل الفطر الشانتيريل، أو فطر المحار، أو الفطر البني، والتي تتطلب متطلبات تخزين مختلفة. يحتاج كل نوع إلى بيئة خاصة به من حيث محتوى الرطوبة ومدى الحرارة. وعندما تُثبّت هذه أنظمة التحكم المعتمدة على المناطق، فإن المرافق تلاحظ عادةً نتائج أفضل من حيث مدة بقاء الفطر طازجاً بعد الحصاد. تساعد ظروف التخزين المحسّنة في الحفاظ ليس على المظهر فحسب، بل أيضاً على الفوائد الغذائية التي تجعل بعض أنواع الفطر ذات قيمة في الاستعمالات culinariale والطبية.

حلول إدارة الرطوبة

دمج تقنية الحواجز البخارية

تعتبر الحواجز البخارية مهمة للغاية للحفاظ على الظروف المثلى داخل غرف التبريد، لأنها تمنع تراكم الرطوبة التي تؤدي إلى مشاكل التكاثف والتي قد تؤثر سلبًا على جودة الفطر. عند تركيب هذه الحواجز بشكل صحيح، يمكن ملاحظة فرق واضح في كمية الطاقة المستهلكة، حيث لا يضطر النظام إلى بذل جهد كبير للحفاظ على استقرار درجات الحرارة. كما أن الفحص الدوري والصيانة تلعبان دورًا مهمًا أيضًا في ضمان متانة هذه الحواجز. من الأفضل فحصها كل بضعة أشهر للبحث عن أي شقوق أو تمزقات وإصلاحها فورًا قبل أن تتفاقم المشكلة. في الواقع، يشمل معظم المزارعين هذه الفحوصات في جدول الصيانة الروتيني الخاص بهم، مما يضمن بقاء الفطر الطازج جاهزًا للتسويق أثناء التخزين.

استراتيجيات صيانة 95% RH

الحفاظ على الهواء عند حوالي 95٪ من الرطوبة النسبية يُحدث فرقاً كبيراً عند تخزين الفطر بحيث لا يفسد بسرعة كبيرة. يجد معظم المزارعين أن تركيب أجهزة إزالة الرطوبة ذات جودة عالية مع القيام بفحوصات دورية للرطوبة يساعد في الحفاظ على استقرار الظروف، مما يقلل من مشاكل التلف. تشير بعض الدراسات إلى ملاحظة مثيرة للاهتمام - إن التحكم الجيد في الرطوبة يطيل بالفعل مدة بقاء الفطر طازجاً بنسبة تصل إلى 20٪، على الرغم من أن هذه النسبة تختلف حسب نوع الفطر المخزّن. بالنسبة لأي شخص يدير مشروعاً تجارياً متعلقاً بالفطر، فإن الاهتمام بهذه الأساسيات يلعب دوراً كبيراً في الحفاظ على المنتج طازجاً لفترة أطول. كما يستثمر الأشخاص الأذكياء هذه الأيام في معدات أفضل لمراقبة الظروف، لأن وجود بيانات مباشرة تعني أنهم يستطيعون تعديل الظروف حسب الحاجة بدلاً من التخمين لمعرفة ما يحدث داخل غرف التخزين.

آليات منع التكاثف

من الضروري للغاية التحكم في التكاثف عند إدارة غرف التبريد بشكل صحيح. وهذا يعني فحص درجات الحرارة بانتظام والتأكد من أن العزل الحراري لم يتأثر في أي مكان. كما يُحدث تركيب أجهزة إزالة الرطوبة الأوتوماتيكية فرقًا حقيقيًا لأن هذه الأنظمة تساعد في تقليل الرطوبة الزائدة قبل أن تتحول إلى مشاكل تكاثف فعلية. بالنسبة لمزارعي الفطر على وجه الخصوص، فإن التحكم الجيد في التكاثف مهم جدًا لأن الظروف الرطبة ستدمر محصولهم بسرعة. تميل فطر الزراعة البيضاء خاصةً إلى التدهور بسرعة إذا تم تخزينها بشكل غير صحيح. لا تحمي مستويات الرطوبة المناسبة الفطر فحسب، بل تقلل أيضًا من الهدر الناتج عن المنتجات الفاسدة. يعلم معظم المزارعين ذوي الخبرة أن الظروف البيئية المستقرة في مرافق التخزين البارد تؤدي مباشرة إلى تحقيق محصول أفضل وجودة أعلى عند موعد شحن الحصاد.

تقنيات التبريد بعد الحصاد

تقنية الدورة الهوائية القسرية

تحقيق تهوية مناسبة للهواء في غرف تخزين الفطر الباردة يجعل كل الفرق في الحفاظ على استقرار درجات الحرارة في المكان بأكمله. عندما ينتشر الهواء البارد بشكل متساوٍ بدلًا من التجمع في مناطق معينة، فإنه يمنع تشكل الجيوب الدافئة التي تبدأ فيها الفطريات بالتعفن وتفقد نضارتها. أظهرت الأبحاث على أنواع مختلفة مثل الفطر البني والشيري تاي أن هذه الأنظمة تقلل بشكل ملحوظ من وقت التبريد مقارنة بالطرق القديمة. يلاحظ المزارعون الذين انتقلوا إلى التبريد القسري فترات أسرع في التبريد وزيادة في عمر التخزين لمنتجاتهم. الفرق ليس فقط في الأرقام على الرسوم البيانية، بل يلاحظ العديد من المزارعين أن الفطر يبدو أكثر نضارة بشكل واضح في السوق عندما يحافظون على تدفق هواء جيد طوال فترة التخزين.

دليل تنفيذ التبريد المائي

يعمل التبريد الهيدروجيني بشكل جيد حقًا لتبريد الفطر بسرعة باستخدام الماء، ولا يؤثر سلبًا على جودتها أيضًا. يعتمد تحقيق نتائج جيدة على مراقبة درجات حرارة المياه وكمية التدفق خلال العملية. يجد معظم المزارعين أن البدء في التبريد الهيدروجيني خلال نصف ساعة من الحصاد يُحدث فرقًا كبيرًا. حيث يقوم النظام بإزالة الحرارة الناتجة عن الحصاد بسرعة نسبية، مما يعني أن الفطر يمكنه الوصول إلى درجة الحرارة المناسبة للتخزين بشكل أسرع مقارنة بالطرق الأخرى. يساعد هذا في الحفاظ على فترات صلاحية أطول دون التسبب في أي ضرر في الملمس أو المظهر.

مبادئ التشغيل لتبريد الفراغ

يعمل التبريد بالتفريغ عن طريق خفض نقطة غليان الماء، مما يساعد على سحب الحرارة بعيدًا عن الفطر بسرعة كبيرة. تعمل هذه التقنية بشكل أفضل على الفطر الورقي أو الأصناف التي تحتوي على الكثير من الرطوبة حيث تحافظ على طراوتها دون إتلاف قوامها. أظهرت الأبحاث أن هذه الأنظمة قادرة على خفض درجات الحرارة بمقدار 20 درجة فهرنهايت تقريبًا خلال دقائق، وهو أمر لا تستطيع الطرق التقليدية منافسته من حيث الحفاظ على جودة الفطر في ذروتها. ما يجعل هذا الأسلوب فعالًا إلى هذه الدرجة هو التبريد الموّحد في جميع أنحاء حمولة المنتج. تلعب هذه التجانسية دورًا كبيرًا في البيئات التجارية حيث تحتاج الغرف الباردة ووحدات التكثيف إلى أداء متّسق عبر الدفعات الكبيرة.

تحليل الفوائد التشغيلية

تحسين العمر الافتراضي

إن حفظ الفطر في غرف باردة يُحدث فرقًا حقيقيًا في مدة بقائها صالحة للاستهلاك، حيث يمكن أن تزداد مدة الصلاحية بنسبة 30٪ تقريبًا. بالنسبة للمزارعين الذين ينتجونها والمتاجر التي تبيعها، فهذا يعني أن الفطر يظل طازجًا لفترة أطول بكثير، مما يساعد على الحفاظ على جودته ويخفض من كمية المنتجات المهدورة. وعند الجمع بين التحكم في درجة الحرارة ومستويات الرطوبة المناسبة داخل أماكن التخزين، فإن ذلك يُحدث عجائب في الحفاظ على مظهر الفطر وطعمه الرائع لأسابيع بدلًا من أيام. وقد ذكر لنا عدد من الموردين أن تحسين ظروف التخزين يؤدي إلى بقاء الفطر لفترة أطول في الأسواق. ولكن هناك ميزة إضافية أيضًا، ألا وهي ارتفاع معدلات البيع لأن المستهلكين يفضلون شراء الفطر الذي يبدو طازجًا على تلك التي بدأت حوافها بالذبول أو التحول إلى اللون البني.

خفض استهلاك الطاقة

استخدام أنظمة حديثة موفرة للطاقة يُحدث فرقاً كبيراً من حيث توفير الكهرباء في مرافق التخزين البارد. لقد شهدنا أن هذا النوع من التحديثات يمكنه خفض فواتير الكهرباء بنسبة تصل إلى 20% وحتى ما يقارب النصف، اعتماداً على طريقة الاستخدام اليومي. تُظهر دراسات صناعية أن الشركات التي تستثمر في تقنيات تبريد محسّنة تحقق وفورات مالية شهرياً، وتحصل أحياناً على مزايا إضافية مثل إعفاءات ضريبية أو منح حكومية لاعتمادها ممارسات صديقة للبيئة. عموماً، تُظهر الحسابات نتائج جيدة على المدى الزمني، مما يعني أن الشركات لا تساعد الكوكب فحسب، بل تتخذ قرارات مالية ذكية أيضاً. تعمل غرف التبريد بسلاسة ونظافة أكبر عندما يستثمر المشغلون في هذا النوع من المعدات بدلاً من الاعتماد على النماذج القديمة التي تهدّر المال والموارد.

إمكانية التوسع الوحدوي

عند بناء مرافق التخزين البارد، يُحدث الاعتماد على الأنظمة المعيارية فرقاً كبيراً في التعامل مع volumes إنتاجية أكبر في المستقبل. إن أعمال زراعة الفطر تتميز في يومنا هذا بقدر كبير من عدم ال predictability، حيث تشهد بعض المواسم طلباً أعلى بكثير من غيرها. ولذلك يتجه العديد من المزارعين إلى الأنظمة المعيارية في الوقت الحالي. فكل ما عليهم فعله هو إضافة وحدات إضافية حسب الحاجة بدلاً من هدم كل شيء والبدء من جديد. تُظهر بعض الأمثلة الواقعية أن الشركات التي انتقلت إلى هذا النهج شهدت تسارعاً في نموها بمقدار 15 نقطة مئوية تقريباً مقارنة بالأنظمة التقليدية. هذا منطقي حقاً – إذ إن القدرة على تعديل العمليات بسرعة عند تغير ظروف السوق تمنح الشركات ميزة حقيقية في الحفاظ على تنافسيتها، وفي الوقت نفسه تجنب التكاليف الكبيرة لإعادة الهيكلة لاحقاً.