Core Components of Cold Room Design Principles

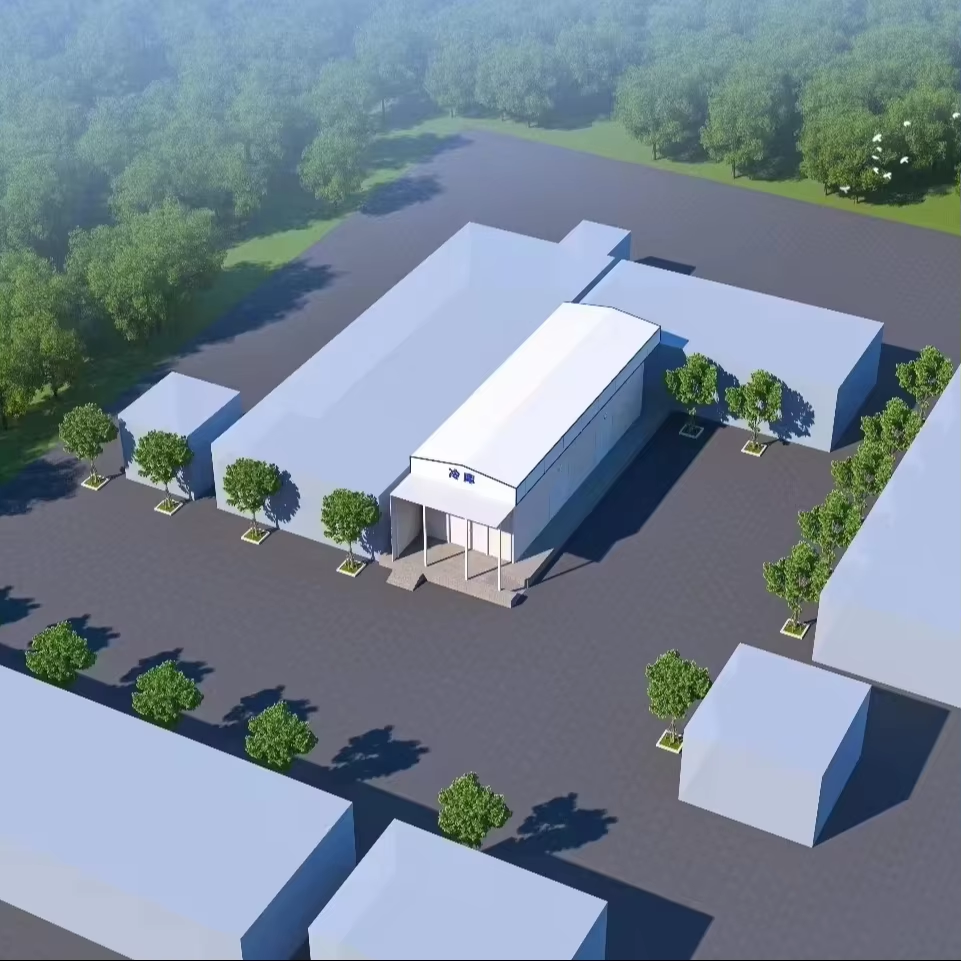

Structural Integrity in Prefabricated Steel Structures

Keeping cold rooms structurally sound matters a lot, especially when it comes to food storage facilities where temperature control is everything. Going with quality materials makes all the difference here. Prefab steel buildings have become pretty popular for cold storage because they can handle extreme temps without breaking down over time. These structures last longer than many alternatives since the steel doesn't warp or degrade like other materials might. When manufacturers put together these prefabs, they create strong joints between components and include steel braces throughout the frame. This reinforcement helps fight off damage from things like moisture buildup, vibration from refrigeration units, and even minor earthquakes in certain regions. Most facility managers will tell you that investing in good construction upfront saves money in repairs later on.

Looking at these structures requires attention to certain design elements that actually make them hold together better. Steel bracing adds extra stability to buildings, and those interlocking parts really help keep everything assembled properly. Meeting standards like ISO 9001 or getting certified by reputable organizations means the work passes basic safety tests for most industries. Following these guidelines does more than just meet minimum requirements it gives clients peace of mind knowing what they see standing there is built to last through normal wear and tear over time.

Thermal Bridging Prevention Techniques

When thermal bridging occurs in cold storage facilities, it lets heat sneak through structural parts which hurts overall energy efficiency. Keeping this from happening helps maintain proper temperatures inside and cuts down on power usage. There are several ways to tackle the problem including adding thermal breaks between materials and properly insulating vulnerable areas. Cold room operators often turn to polyurethane panels for their walls because they offer excellent insulation properties. These panels create a barrier against heat movement, making them a popular choice for facilities looking to improve their energy performance without major structural changes.

Numerous investigations point to how well these approaches work in practice. Thermal breaks when properly installed can cut down on energy costs somewhere around 20 percent according to recent findings, which makes them pretty valuable additions to any system. When it comes to keeping temperatures stable inside cold rooms, good insulation matters a lot too. Panels made from high quality insulating materials do wonders at maintaining consistent conditions throughout storage areas. For anyone looking to improve their cold storage efficiency, getting familiar with these methods isn't just helpful it's almost necessary if they want to save money on electricity bills without compromising product quality.

Advanced Insulation Strategies for Temperature Control

Polyurethane vs. Insulated Cold Room Panels Comparison

Looking at different insulation materials for cold storage areas means comparing how polyurethane panels stack up against alternatives before making any choices. These panels really stand out when it comes to keeping heat out, so temperatures stay stable even in extreme conditions. Many businesses find them worth the investment because they tend to save money over time. Some other insulated panels could still be good options too, especially if installation is a concern. The lighter weight makes these panels faster to put in place, cutting down both labor expenses and production delays during setup. Industry professionals regularly point to polyurethane as top performer in insulation efficiency, noting that facilities using this material typically see noticeable drops in monthly energy bills after installation.

Vapor Barrier Integration Methods

Vapor barriers are essential for keeping temperatures stable in cold room designs because they stop moisture from building up inside walls and ceilings. Without these barriers, we often see mold problems develop along with wasted energy costs. When warm outside air hits those chilly interior surfaces in storage rooms, condensation forms naturally unless there's something stopping it. That's why smart builders plan ahead for vapor barriers during construction phases. They need to place these barriers carefully at spots where temperature changes happen most frequently and pick materials that work well with whatever insulation is already installed. Industry pros usually recommend putting barriers right between different insulation layers or going with polyethylene sheets for best results. Research shows good vapor barrier installation can really make a difference too. Some studies point to around 40% fewer mold issues after proper installation, which means better performance overall and cleaner conditions for stored goods. Most cold storage operators find that investing in quality vapor barriers pays off through lower maintenance headaches and longer equipment life spans.

Mechanical Systems Configuration

Industrial Condensing Unit Selection Criteria

Picking the right industrial condensing unit makes all the difference when it comes to getting good cooling performance while keeping energy bills down. There are several things worth thinking about before making a purchase decision. First off, matching the unit's capacity to what the facility actually needs prevents problems where the system either struggles to keep up or wastes power running too hard. Energy efficiency matters a lot too. Units that come with better efficiency ratings tend to save money in the long run and help companies meet their green targets. Environmental considerations have become pretty significant these days because of all the rules governing greenhouse gas emissions. Refrigerants used in older systems often don't pass current standards, so checking what kind of refrigerant a unit uses before buying can save headaches later on.

What kind of refrigerant gets used makes a big difference in how well a system cools things down and whether it meets all those regulations hanging over the industry. Some options just work better for energy consumption and happen to be easier on the environment too. Take natural stuff like CO2 or ammonia for instance these have been catching on lately because they don't contribute much to global warming. Picking between different refrigerants affects whether companies stay within legal boundaries set by agreements such as Kyoto Protocol, plus it helps protect investments when new rules come along. Looking at actual cases shows why this matters so much. There are plenty of examples where businesses switched to greener alternatives and saw both lower emissions numbers and actual cost reductions in day to day operations, something that fits right into what most countries are trying to achieve with their environmental goals.

Refrigerant Circuit Optimization

Getting a good grasp on how refrigerant circuits work and making sure they're optimized makes all the difference when it comes to running an efficient cooling system. These circuits basically consist of several key parts including compressors, condensers, evaporators, and those little expansion valves we often overlook. Each component has its own job in keeping things cool throughout the whole process. When everything works together properly, that's what determines if the system runs efficiently or not. That's why getting the setup right matters so much for performance. A poorly configured circuit can lead to wasted energy and higher operating costs down the line.

Getting the most out of systems starts with proper component sizing and smart control integration. When parts are sized right for their job, they run better without wasting power or breaking down prematurely. The latest control tech takes this a step further, making adjustments on the fly based on what's actually happening in the system at any given moment. This cuts down on wasted energy across the board. Looking at what's happening in the field, we see clear evidence that optimized circuits deliver real results. Some studies show efficiency gains around 30% when everything works together properly. These kinds of improvements aren't just good for the bottom line either. Companies that implement these methods typically see lower operating costs while also reducing their overall energy footprint, which matters more than ever as industries face increasing pressure to operate sustainably.

Sustainable Steel Structure Implementation

Energy-Efficient Framing Techniques

When building cold storage facilities, energy efficient framing methods make all the difference in keeping those temperatures down while saving on power bills. Most modern cold rooms rely heavily on insulated panels that stop heat from leaking in or out. These aren't just regular panels either - many contain polyurethane foam sandwiched between metal layers, which acts like a super thick blanket for the building. The steel frames themselves have gotten smarter too. Prefab construction means fewer mistakes during installation and less material going to waste. Take the big warehouse down in Kansas City for instance. They retrofitted their entire facility with these new systems last year and saw their monthly electricity tab drop by almost a quarter. That kind of saving adds up fast when we're talking about industrial scale operations running 24/7.

Recyclable Material Integration

Adding recyclable materials to cold room construction really makes a difference for our planet. When builders go with stuff like aluminum or certain kinds of steel that can be recycled again and again, it cuts down on environmental damage while keeping those materials useful longer. Cold rooms built this way stay just as strong structurally, plus they might actually save money over time. Take recycled steel for example the World Steel Association reports something around half fewer carbon emissions compared to regular steel construction. And let's face it, cutting down on carbon footprints across construction sites matters a lot these days. More companies are looking at their buildings through green glasses now, trying to meet those international eco standards without breaking the bank.

Operational Efficiency Enhancements

Modular Layouts for Scalability

Cold rooms built with modular layouts bring real benefits when it comes to scaling operations and adapting over time. Traditional setups are pretty rigid once installed, but modular systems let companies grow or change configuration without major headaches. Take food processors for instance many begin with basic storage solutions then add modules as production ramps up. These designs typically use pre-made steel components that snap together quickly making modifications straightforward. Companies switching to this approach tend to see around 20% better efficiency according to industry reports because they spend less time and money on rearranging spaces when needs shift.

Preventive Maintenance Protocols

Keeping cold rooms running smoothly requires good preventive maintenance practices. When companies fix small problems before they turn into big ones, everyone saves money and keeps operations going without interruptions. A solid maintenance plan means setting up regular checkups, looking closely at all the equipment, and making sure staff knows what to do when things need fixing. One real world example shows what happens when businesses get serious about maintenance routines. After implementing strict maintenance protocols, a food storage company cut down on downtime by around 30 percent and actually spent 15% less each year on repairs. Numbers like these show why many smart operators now see maintenance not just as a chore but as part of their bottom line strategy.