In any cold storage facility, the cold room door serves as the most critical interface between the controlled internal environment and the external ambient conditions. It is not only a physical access point but also a vital component in maintaining the cold chain integrity, ensuring temperature stability, and preventing energy loss. A well-designed cold room door must provide superior thermal insulation, airtight sealing, mechanical durability, and operational convenience. Modern cold room door is engineered with advanced materials and technologies to meet stringent industrial requirements in food processing, pharmaceuticals, logistics, and supermarkets.

1. Characteristics of Cold Room Doors

Thermal Insulation Performance

The primary characteristic of a cold room door is its excellent thermal insulation. Most doors use a sandwich construction consisting of a rigid polyurethane (PU) or polyisocyanurate (PIR) foam core between two metal sheets—typically pre-painted galvanized steel or stainless steel. The insulation layer ensures minimal heat transfer between the external and internal environments, helping to maintain stable temperatures inside the cold room. The foam density typically ranges between 38–45 kg/m³, and the door thickness varies from 60 mm for chillers to 120 mm for freezers.

Airtight Sealing System

Cold room doors are equipped with airtight gaskets made of flexible rubber or PVC to prevent air leakage. The sealing design may include magnetic gaskets or compression-type seals, which ensure tight closure even under pressure differentials. A high-quality seal reduces energy loss, prevents frost buildup, and maintains humidity balance inside the room.

Door Heating System

In low-temperature applications (below –10°C), doors are fitted with heating elements around the frame or threshold to prevent ice formation that could hinder operation. These heater wires, usually made from self-regulating cables, maintain a frost-free surface and ensure smooth door function even in deep-freeze conditions.

Structural Strength and Durability

Cold room doors are constructed with reinforced frames and hinges capable of withstanding repeated opening cycles and mechanical stress. The door panel’s steel skins and inner reinforcements prevent warping, bending, or deformation caused by temperature differences. Stainless steel hardware and anti-corrosive coatings further enhance durability in humid or saline environments.

Hygienic Design and Easy Cleaning

Because cold rooms are used for food and pharmaceuticals, hygiene is crucial. Door surfaces are smooth, non-porous, and corrosion-resistant, preventing bacterial growth and facilitating easy cleaning. The materials used are compliant with HACCP and ISO 22000 hygiene standards.

Variety of Types

Cold room doors come in several types depending on the application and available space:

- Hinged doors – ideal for small to medium cold rooms; simple and cost-effective.

- Sliding doors – suitable for large cold rooms or frequent use; save space and support manual or automatic operation.

- Swing doors – used for processing rooms or high-traffic areas.

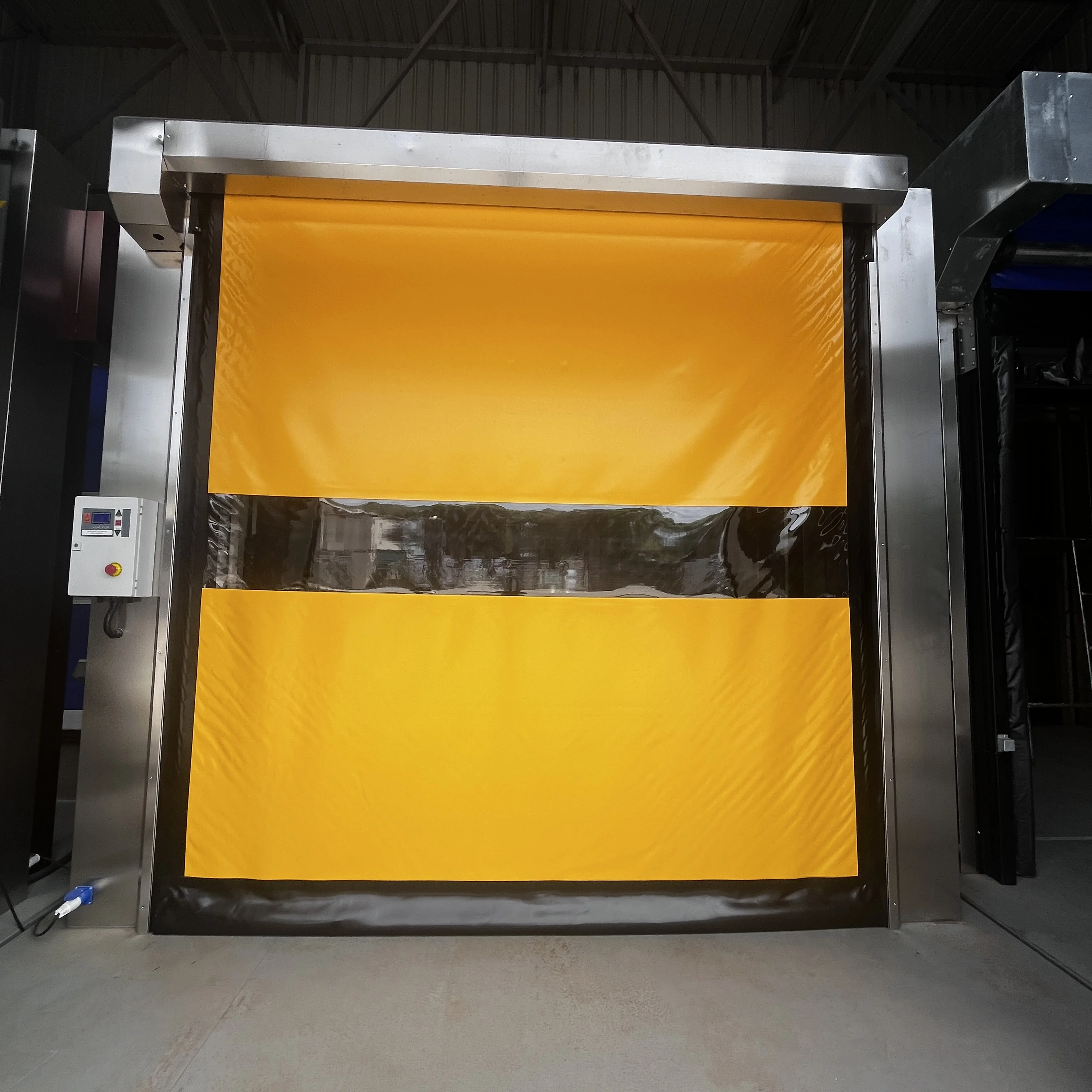

- Fast-rolling doors – designed for rapid operations, maintaining temperature stability during frequent access.

Safety and Automation Features

Many modern cold room doors include automatic closing systems, emergency release handles, door limit sensors, and photoelectric safety sensors. Automatic sliding or high-speed doors are integrated with motorized systems controlled by microprocessors, allowing smooth and safe operation.

2. Advantages of Cold Room Doors

Energy Efficiency and Temperature Stability

The insulation and airtightness of cold room doors significantly reduce thermal exchange, ensuring that the refrigeration system operates efficiently. A properly sealed door can reduce energy consumption by up to 20–30% compared to conventional non-insulated doors. The heating system also helps prevent frost accumulation, maintaining energy efficiency over long-term use.

Operational Convenience and Safety

Cold room doors are designed for ease of use. Sliding and automatic types enable smooth, low-effort operation, even for large or heavy panels. Safety features such as emergency release systems ensure that personnel can exit from inside the cold room even if the door is locked, preventing accidents.

Hygienic and Aesthetic Appearance

The clean, polished surface of the door complements the sanitary design of cold storage environments. Materials such as stainless steel (SUS304) or coated galvanized steel not only provide durability but also maintain an aesthetic, professional appearance in food and pharmaceutical facilities.

Durability and Long Service Life

Cold room doors are engineered for long-term reliability. The combination of corrosion-resistant materials, reinforced hinges, and robust insulation panels ensures minimal wear even after thousands of opening and closing cycles. Properly maintained doors can last 15–25 years or longer.

Noise and Moisture Control

In addition to thermal insulation, cold room doors also act as effective barriers against external noise and moisture. Their multi-layer construction and tight seals create a stable microclimate within the cold room, protecting stored goods from environmental fluctuations.

Flexibility and Customization

Manufacturers offer cold room doors in various configurations—single-leaf, double-leaf, manual, or automatic—and customized dimensions to suit project requirements. Color, surface finish, and hardware can also be tailored to match specific industry or branding needs.

3. Key Considerations During Manufacturing

Producing a high-quality cold room door requires precision engineering and strict quality control. Below are the key aspects manufacturers must pay attention to during production.

Material Selection

The door panel’s outer skin must be corrosion-resistant and durable. Common materials include pre-painted galvanized steel, stainless steel, or aluminum alloy. The insulation core should have a consistent density and closed-cell structure for high thermal efficiency. Polyurethane (PU) and PIR foams are the most popular choices due to their low thermal conductivity and moisture resistance.

Frame Design and Thermal Breaks

The frame must be robust and properly sealed to the cold room wall. Thermal breaks (insulated barriers between the inner and outer frame) are essential to prevent condensation and heat transfer. Aluminum profiles with PVC inserts are commonly used for this purpose.

Precision Assembly and Alignment

Manufacturing accuracy is critical for ensuring airtight closure and smooth operation. The door leaf and frame must align perfectly, and all joints must be properly sealed with gaskets or silicone. Poor alignment can cause air leaks, frost buildup, and increased energy consumption.

Heating System Integration

For freezer doors, the installation of door heaters must be reliable and safe. Heating cables should be properly embedded in the frame and threshold, with moisture-resistant insulation and thermostatic control to prevent overheating or electrical faults.

Hardware and Accessories

Hinges, locks, rollers, and handles should be made of stainless steel or high-strength composite materials for durability and hygiene. In sliding doors, the guide rail system must allow smooth, low-friction movement while maintaining a tight seal when closed.

Testing and Quality Assurance

Before delivery, each door should undergo comprehensive testing, including airtightness, insulation performance, electrical safety (for heaters), and operational endurance. Doors must meet international standards such as ISO 9001, CE, or EN 13241-1 for industrial doors.

Compliance with Safety Standards

All cold room doors should include emergency release handles, ensuring that workers cannot be trapped inside. For automatic models, sensors and limit switches must comply with safety regulations to prevent injury.

4. Technical Specifications

Below is a summary of standard technical parameters for cold room doors used in commercial and industrial refrigeration facilities:

|

Item |

Specification |

|

Door Type |

Hinged / Sliding / Swing / Automatic / High-Speed |

|

Panel Thickness |

60 mm (chiller), 100–120 mm (freezer) |

|

Insulation Core |

Polyurethane (PU) or Polyisocyanurate (PIR), density 38–45 kg/m³ |

|

Thermal Conductivity |

0.018–0.024 W/m·K |

|

Surface Material |

PPGI, Stainless Steel (SUS304), or Aluminum Alloy |

|

Frame Material |

Aluminum alloy or stainless steel with thermal break |

|

Sealing System |

Magnetic or compression rubber gasket |

|

Heater Type |

Self-regulating heating cable for –10°C and below |

|

Opening Method |

Manual or motorized with control system |

|

Operating Temperature Range |

+15°C to –40°C |

|

Air Leakage Rate |

≤ 1.5 m³/h·m² at 50 Pa |

|

Fire Rating |

Class B-s2-d0 (PU/PIR core) |

|

Power Supply (Heater/Automation) |

220V/1Ph/50Hz or as specified |

|

Certifications |

ISO 9001, CE, EN 13241-1, HACCP compliant |

ONLINE

ONLINE