Superior Thermal Insulation and Energy Efficiency

How Polyurethane (PU) Foam Delivers High Thermal Resistance

Polyurethane foam's closed-cell structure provides exceptional thermal resistance, with an R-value of 5.8–6.5 per inch—35% higher than traditional options like expanded polystyrene (EPS). This performance stems from gas-filled cells that minimize heat transfer through conduction and convection, making PU sandwich panels ideal for maintaining stable sub-zero temperatures.

Comparative R-Values: PU Sandwich Panels vs. Traditional Insulation

| Material | R-Value per Inch | Thickness Needed for R-30 |

|---|---|---|

| PU Sandwich Panels | 6.0 | 5 inches |

| Fiberglass Batt | 3.2 | 9.4 inches |

| EPS Foam | 4.0 | 7.5 inches |

| Mineral Wool | 3.3 | 9.1 inches |

Data from comparative insulation studies shows PU panels require 33–47% less material to achieve equivalent insulation, reducing both construction costs and lost storage space in cold rooms.

Reducing Energy Consumption and Operational Costs in Cold Storage

The superior R-value of PU sandwich panels directly lowers HVAC runtime, cutting energy consumption by 20–30% compared to facilities using fiberglass insulation. For a 50,000 sq ft frozen warehouse, this translates to annual energy savings of $15,000–$22,000 based on 2024 electricity rates.

Case Study: Energy Savings in a Frozen Food Warehouse with PU Panels

A seafood distribution center in Chicago reduced refrigeration costs by 28% after replacing mineral wool insulation with PU sandwich panels. Over three years, the upgrade saved $189,000 in energy expenses, achieving full return on investment within 4.2 years.

Durability and Performance in Harsh Cold Storage Environments

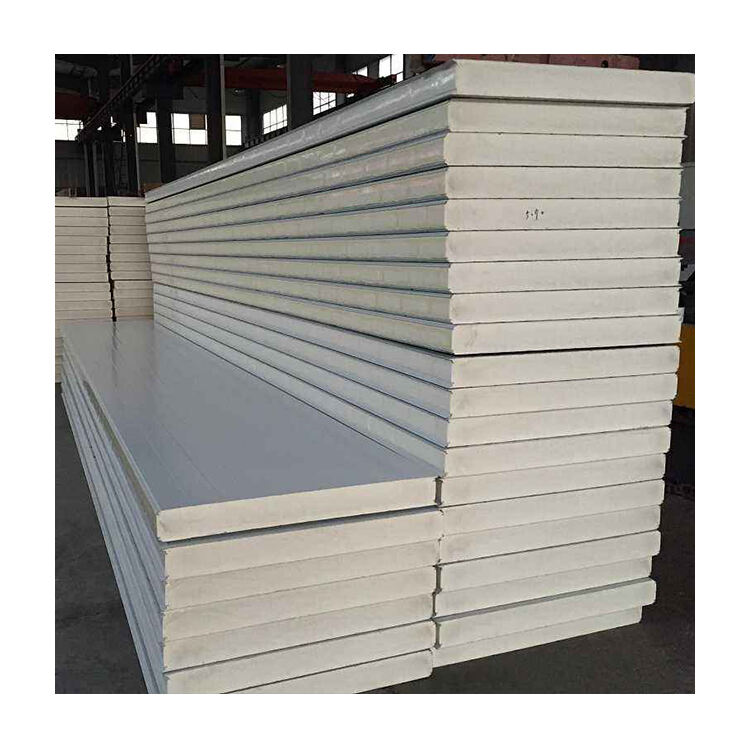

Structural Strength and Load-Bearing Capacity of PU Sandwich Panels

PU sandwich panels integrate high-density polyurethane cores with galvanized steel facings, achieving load-bearing capacities of 300–450 kg/m²—40% higher than EPS alternatives. This structural integrity supports safe multi-level stacking in cold storage, as validated by a 2023 International Cold Chain Association study on industrial insulation materials.

Resistance to Moisture, Corrosion, and Microbial Growth

The non-porous PU foam structure absorbs less than 1.2% water, eliminating corrosion risks common in metal-clad fibrous insulation. Independent testing shows PU panels reduce microbial colonization by 98% compared to mineral wool, meeting FDA food safety standards for high-humidity environments.

Long-Term Performance in Sub-Zero and High-Humidity Conditions

Accelerated aging tests simulating 10 years of -30°C exposure demonstrate that PU sandwich panels retain 95% of their initial thermal resistance, outperforming EPS by 27% (ScienceDirect, 2024). This resilience prevents thermal bridging from material degradation, ensuring consistent temperatures even in facilities with frequent door cycling.

Compliance with Cold Storage Safety and Insulation Standards

Meeting International Insulation and Construction Requirements

Polyurethane sandwich panels have been designed to meet all the major cold storage industry standards around the world. They follow ISO 22000 when it comes to keeping food safe, plus they work with local rules too, like those set out by the FDA under their Current Good Manufacturing Practices. What makes these panels stand out is their ability to maintain good insulation properties throughout their lifespan. The R-value can reach as high as 8.7 per inch thickness, which means buildings stay at the right temperature without wasting energy. Plus, these panels can handle being part of load-bearing structures both on walls and ceilings. The special closed cell core inside really helps keep air from leaking through, something that's absolutely critical for facilities where temperature control must be maintained at all times according to construction regulations.

Fire Safety Ratings and Regulatory Approvals for PU-Based Systems

Today's polyurethane sandwich panels actually pass those important fire safety tests like ASTM E84 Class 1 and the European standard EN 13501-1 B-s1,d0. The special flame-resistant core material really does make a difference when it comes to slowing down how fast fires can spread through a building. And let's not forget about those metal outer layers that won't catch fire at all, so there's no dangerous smoke coming out during emergencies. This matters a lot for places where they store medicines or food products that need cold storage conditions. Facility managers find these characteristics extremely helpful for meeting all sorts of fire codes including NFPA standards and International Building Code specifications specifically for cold storage areas.

Industry Trend: Shift Toward Prefabricated PU Sandwich Panel Systems

According to recent studies, around 63 percent of all new cold storage facilities are going with those pre-made PU panels these days. The reason? When manufacturers control everything at the factory level, they can pretty much guarantee that insulation meets specs and safety requirements stay consistent across installations. What this means for contractors is fewer mistakes happening right there on-site, plus easier time keeping track of paperwork when auditors come knocking. Regulations keep getting stricter in both food storage and medicine transport industries, so having documentation ready becomes absolutely critical. Plus, the modular nature of these panel systems makes it possible to retrofit buildings later on as green building standards continue to evolve. Many companies are already working toward achieving certifications such as LEED Zero Energy status through incremental improvements made possible by this flexible approach.

Fast Installation and Design Flexibility for Custom Cold Storage

Streamlined Assembly and Reduced Construction Timelines

PU sandwich panels feature lightweight, prefabricated designs with interlocking joints and pre-cut openings for refrigeration systems, significantly reducing on-site labor. One facility achieved a 40% reduction in assembly time by replacing masonry walls with PU panels, accelerating project completion without compromising structural integrity.

Customization Options for Diverse Storage Layouts and Sizes

PU panels come in modules that let businesses configure them just right for different temperature needs, vertical spaces, or weird-shaped areas where standard panels won't fit. They're made in sizes from about 60mm thick all the way up to 200mm and widths between roughly 950mm and 1200mm. These dimensions work well across a broad spectrum of settings including those super cold -30 degree freezers as well as the more temperate rooms where fruits and vegetables need controlled humidity levels. According to a recent industry report from last year, most logistics companies (around three out of four) are now looking for insulation solutions that can be customized because their inventory changes so much throughout the seasons.

Integration with Sustainable and Modular Cold Storage Projects

PU panels support sustainable construction through reusable designs and energy-efficient production. Their compatibility with solar-powered refrigeration and rainwater harvesting systems enhances net-zero initiatives. In a 2024 temperature-controlled pharmaceutical facility, modular PU panel installations reduced material waste by 32% compared to conventional construction methods.

FAQ Section

What is the main benefit of using PU sandwich panels in cold storage?

PU sandwich panels offer superior thermal insulation with high R-values compared to traditional materials, resulting in decreased energy consumption and lower operational costs.

How do PU panels compare with other insulation materials?

PU panels have a higher R-value per inch, requiring less thickness to achieve the same insulation performance as materials like fiberglass, EPS, or mineral wool.

Are PU sandwich panels environmentally friendly?

Yes, PU panels support sustainable practices through reusable, energy-efficient designs and are compatible with solar and rainwater systems, contributing to net-zero construction.

Do PU panels comply with safety standards?

PU panels meet international insulation and construction standards, fire safety regulations, and FDA food safety requirements for cold storage environments.