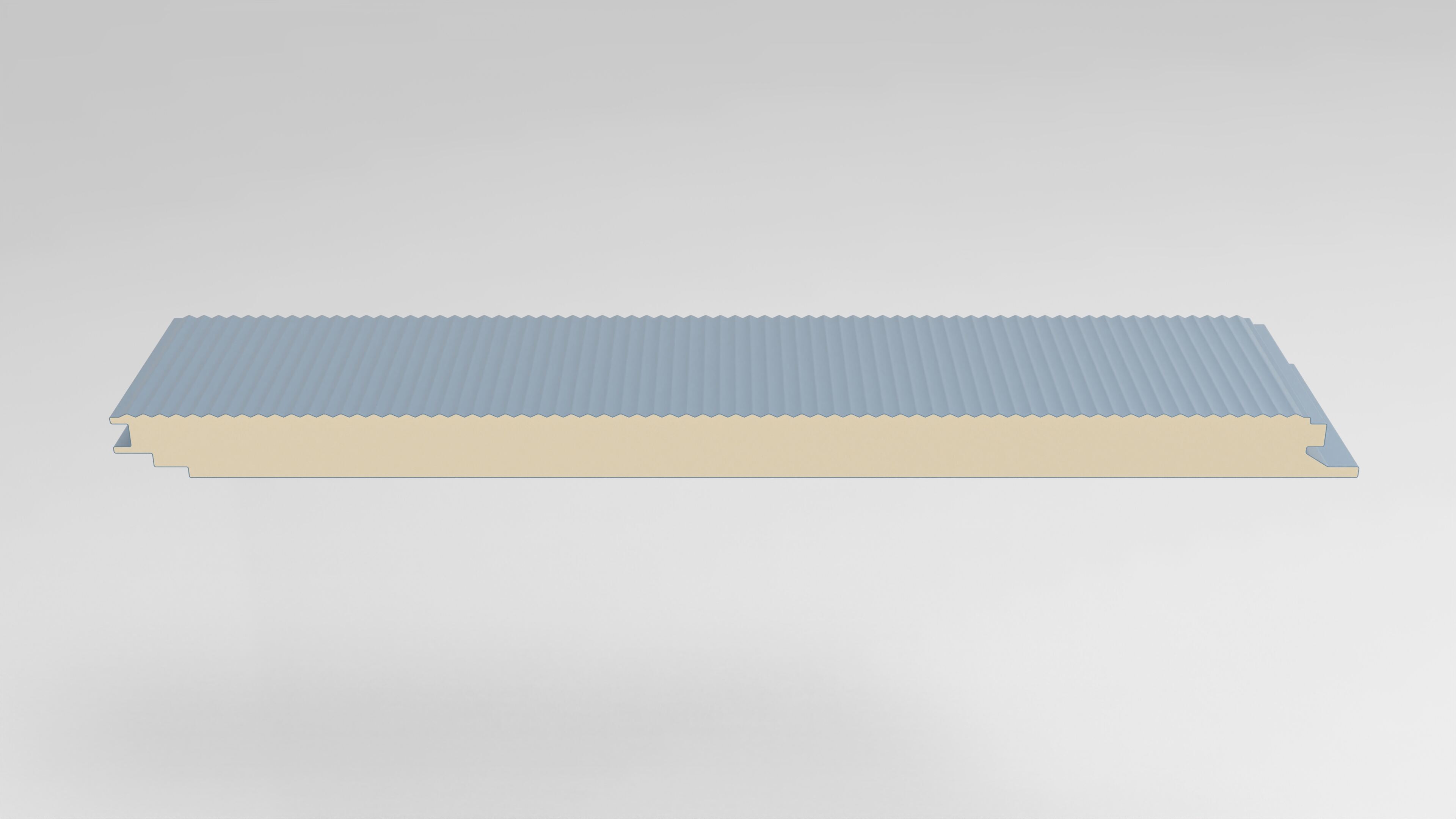

Superior Thermal Insulation Properties of PU Sandwich Panels

Polyurethane (PU) sandwich panels offer exceptional thermal performance for cold storage facilities, thanks to the advanced engineering of their polyurethane foam core. With a thermal conductivity range of 0.022–0.028 W/m·K, PU foam provides superior heat resistance—equivalent to using insulation that’s 30% thicker when compared to traditional materials.

How Polyurethane Core Enhances Thermal Performance in Cold Storage

PU foam's closed cell structure keeps most of those inert gases trapped inside about 95% of the material itself. This creates tiny air pockets throughout the foam that actually stop heat from moving through it either by conduction or convection. The way this works makes a big difference when it comes to thermal bridging problems we often see with fiberglass or mineral wool insulation. Even minor gaps in these materials something like just 3% openings can lead to around 20% more energy loss according to ASHRAE research from 2023. That kind of efficiency matters a lot for building performance over time.

Comparative Analysis: PU Panels vs. Other Insulation Materials

| Material | R-Value per Inch | Moisture Resistance | Service Life (Years) |

|---|---|---|---|

| PU Sandwich Panels | 6.8 | Non-absorbent | 30+ |

| Expanded Polystyrene | 4.0 | Moderate absorption | 15 |

| Mineral Wool | 3.3 | High absorption | 10 |

Polyurethane panels keep about 98% of their insulation value even after sitting in those brutal -30 degree Celsius conditions for 15 whole years. That's way better than polystyrene options, which tend to lose around 40% of their effectiveness when exposed to similar cold over time. Another big plus is how these panels don't soak up moisture, so there's no chance of mold growing on them. This matters a lot in places like refrigeration warehouses where humidity levels are always high. Facilities report seeing roughly a two thirds reduction in microbial issues when switching to PU systems according to FDA guidelines for cold chain storage. The bottom line? Buildings equipped with these panels typically consume between 22 to 30 percent less energy each year. Not only does this help satisfy those strict NSF/3-A sanitation requirements, it also means companies start seeing their money back faster from the initial investment.

Energy Efficiency and Sustainability Benefits in Cold Storage Design

Reducing Refrigeration Load and Operational Energy Use

PU sandwich panels reduce refrigeration energy demand by 30–40% due to their continuous, high-performance thermal barrier. By minimizing heat exchange, these panels decrease compressor runtime and allow for smaller, more cost-effective refrigeration systems—lowering both initial equipment costs and long-term energy use.

Quantifying Energy Savings: Insights from USDA and Industry Data

Research from 2023 looking at cold storage warehouses showed that buildings insulated with polyurethane saved between 18 and 22 percent on yearly energy bills compared to ones with expanded polystyrene insulation. The USDA numbers back this up, pointing to savings around 40 to 55 cents per square foot each year. Take a typical 100 thousand square foot operation for example. At those rates, operators could cut their annual energy costs close to $45k. That kind of saving really makes a difference when it comes to return on investment too. Facilities switching to PU insulation often see their payback period shrink by almost half compared with other insulation options available today.

Integration with Renewable Energy Systems for Net-Zero Cold Storage

PU panels can cut down on basic energy requirements somewhere around 35 to 40 percent, which means solar panels and geothermal systems can actually cover most of what a building needs for power these days, maybe even 60 to 75%. When we put these things together, it really helps reduce carbon footprints. Cold storage warehouses are seeing some amazing results too, cutting their carbon emissions by nearly 90% in some cases. Look at Europe where several warehouses have hit that sweet spot of zero net emissions thanks to good old PU insulation working hand in hand with renewable energy sources.

Structural Durability and Hygienic Advantages of PU Sandwich Panels

Performance Under Sub-Zero Temperatures and High Humidity

PU sandwich panels remain dimensionally stable and structurally sound in temperatures as low as -40°C. Even at 95% relative humidity, the core retains 96% of its compressive strength (ASCE 2022), outperforming materials like EPS that are prone to degradation under similar conditions.

Moisture, Mold, and Corrosion Resistance in Critical Environments

With less than 0.5% water absorption (ASTM C272), PU panels effectively block moisture ingress—compared to 4–6% in mineral wool. This inherent resistance prevents corrosion and creates an inhospitable environment for mold, making them ideal for demanding settings such as seafood processing plants with saline exposure.

Hygienic Surface Finishes and Compliance with Food Safety Standards

Featuring seamless, non-porous steel facings, PU panels meet NSF/ANSI 2 standards for food contact surfaces and support hospital-grade sanitation protocols. Optional antimicrobial coatings reduce bacterial colonization by 99.8% (Journal of Food Protection 2023), ensuring compliance in pharmaceutical storage and USDA-regulated meat processing environments.

Design Flexibility and Fast Installation in Modular Cold Storage Projects

PU sandwich panels enable rapid deployment of modular cold storage solutions, cutting construction time by up to 60% versus conventional methods. Pre-engineered wall and ceiling modules arrive on-site with integrated vapor barriers and thermal breaks already installed, allowing medium-sized facilities to be operational in just 4–6 weeks.

Prefabricated Panel Systems for Rapid Deployment

Precision manufacturing allows PU panels to be pre-cut to exact project specifications, supporting assembly rates of 300–500 m² per day. This approach eliminates weather-related delays and ensures consistent thermal performance (R-value ≥ 5.5 per inch) throughout the building’s lifespan.

Customization Options: Sizes, Finishes, and Joint Sealing Technologies

Available in thicknesses from 60mm to 200mm, PU panels can be tailored for applications ranging from chilled storage (-5°C) to deep-freeze environments (-30°C). Advanced tongue-and-groove joints with dual-seal gaskets achieve air leakage rates below 0.05 cfm/ft², exceeding critical food safety and hygiene requirements.

Case Study: Modular Cold Storage in Pharmaceutical Logistics

A 12,000-pallet pharmaceutical logistics facility utilizing PU panels became fully operational in 28 days—45% faster than traditional construction. The airtight envelope reduced annual refrigeration energy demand by 22% and met strict EU GMP standards for surface cleanliness and sanitation.

FAQ

What are the main benefits of using PU sandwich panels for cold storage?

PU sandwich panels offer superior thermal insulation, energy efficiency, moisture resistance, and structural durability, making them ideal for cold storage facilities.

How do PU panels compare to other insulation materials?

PU panels have higher R-values per inch, non-absorbent moisture resistance, and a longer service life compared to materials like expanded polystyrene and mineral wool.

Can PU sandwich panels help reduce energy costs?

Yes, PU panels can significantly reduce energy costs by decreasing refrigeration load, operational energy use, and integrating with renewable energy systems.

Are PU sandwich panels resistant to mold and corrosion?

Yes, PU panels provide effective moisture, mold, and corrosion resistance, making them suitable for environments with high humidity and exposure to saline.