The Role and Working Principle of Condensing Units in Refrigeration

Definition of a Condensing Unit and Its Place in the Refrigeration Cycle

The condensing unit serves as the high pressure part of the system where refrigerant gets compressed and turned into liquid form within cooling systems. Sitting right after the compressor but before the expansion valve, this component finishes off what we call the vapor compression cycle by getting rid of all that heat picked up inside refrigerated areas. What makes this whole loop work so well is that it maintains stable temperatures across different settings. Think about those big walk-in freezers at grocery stores or even the special storage rooms used for keeping medicines at just the right temperature. Without proper condensing action, these environments would struggle to stay consistently cold enough for their intended purposes.

Function of the Condenser Unit in Cooling Systems: Heat Rejection and Refrigerant Condensation

The main job of these units is twofold really. First, they get rid of excess heat into the surrounding air, and second, they turn vapor refrigerant back into liquid state. When heat moves through those metal coils and fin structures, it helps keep the right pressure difference going so the cooling cycle can continue uninterrupted. Getting this heat rejection right matters a lot because when systems fail to reject enough heat, compressors start working harder than they should. This extra strain leads to faster component breakdowns. Some industry research suggests that proper heat management can actually extend equipment life by around 25%, which makes good business sense for maintenance budgets.

How Does a Condensing Unit Work? A Breakdown of the Core Process

The process involves four stages:

- High-pressure refrigerant gas enters the condenser coils from the compressor

- Ambient air or water absorbs heat from the coils via forced convection

- The refrigerant cools below its saturation point, transitioning to liquid

- Liquid refrigerant flows to the expansion valve for pressure reduction

As noted in thermal efficiency analyses, this phase change process removes 95-98% of heat from the refrigeration cycle.

Role of Condensers in Heat Rejection and Refrigerant Condensation

Effective heat rejection directly impacts system performance. Underloaded condensers cause refrigerant subcooling, wasting 15-30% of cooling capacity. Conversely, oversized units increase energy consumption by cycling excessively. Modern designs use variable-speed fans and microchannel coils to balance heat transfer rates with operational demands, achieving >20% efficiency gains in USDA-compliant cold storage systems.

Core Components and Their Contribution to System Performance

Core components of the condenser unit: Compressor, condenser coil, fan, and expansion valve

Condensing units these days depend on about four main parts to get those refrigeration cycles going. First off, there's the compressor which works kind of like the heart of the whole system, pumping up refrigerant gas so it gets hotter. Once this high pressure vapor moves into the condenser coil, heat starts to escape through those metal fins made from either aluminum or copper. Some systems even have these big fans blowing air across the coils at high speed to push out all that unwanted heat. Last but not least comes the expansion valve, which controls how much refrigerant goes into the evaporator part. This control is pretty important because it creates those pressure drops needed for refrigerant to actually change states from liquid back to gas again.

How each component contributes to the heat exchange process in condenser units

Every component plays a role in how well heat gets transferred through the system. The compressor sets the stage by determining what kind of thermal load the refrigerant starts with. Meanwhile, bigger condenser coils can reject heat faster than smaller ones simply because they have more surface area available for this process. Fans help manage things too by controlling airflow across those coils so temperatures stay within safe limits and prevent the whole system from getting overloaded. And let's not forget about the expansion valve which acts like a gatekeeper, making sure refrigerant enters the evaporator at just the right pressure temperature combination. This balance between cooling power and actual energy consumption is what keeps these systems running efficiently day after day.

Interplay between refrigeration cycle components for optimal performance

How different parts work together determines whether a system will run reliably day after day. Take compressors and condenser coils for instance. If the compressor produces too much refrigerant for what the coil can handle, problems start happening fast. We've seen systems short cycle themselves into oblivion or just plain overheat because someone missed matching sizes properly during installation. The same goes for fans running at just the right speed. When temperatures outside go up and down, those fans need to adjust accordingly so condensation doesn't get out of control. Maintenance matters too. Dirty coils and off-calibrated valves throw everything off balance. Real world data shows something interesting: cleaning condenser coils to remove about 15% of built up dirt boosts heat transfer performance around 20%. That small fix makes a big difference across the whole system when all these components are working in harmony instead of fighting each other.

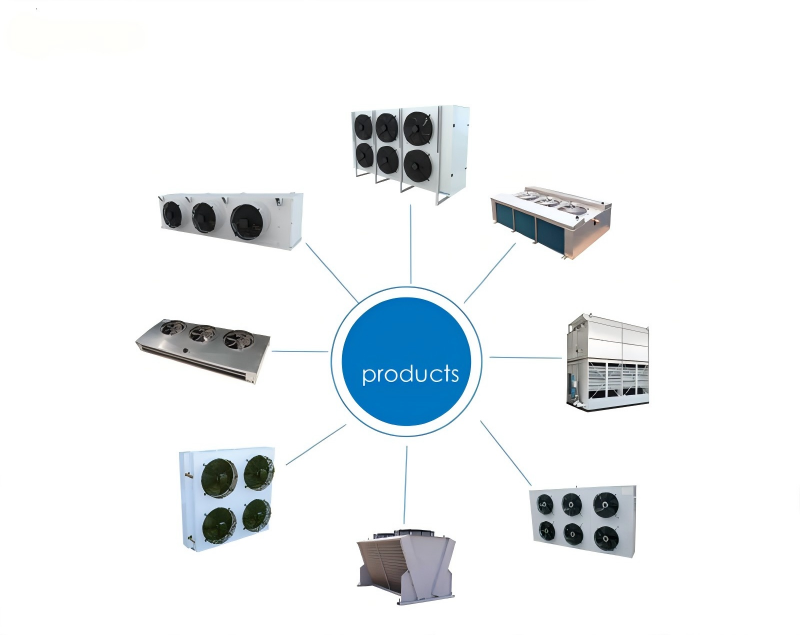

Types of Condensing Units and Their Application-Specific Advantages

Air-Cooled, Water-Cooled, Evaporative, and Adiabatic Condenser Types Compared

There are basically four main kinds of condensing units when we look at how they reject heat: air cooled ones, water cooled models, evaporative types, and the newer adiabatic systems. Most businesses go for air cooled units in smaller operations because they're straightforward to install and don't need much extra equipment. Water cooled systems tend to perform better though, giving around 15 to maybe even 30 percent more efficiency in big industrial plants where space isn't an issue. Evaporative condensers work really well in dry areas since they mix both air and water cooling techniques. These can cut down on energy costs by about 35% compared to just regular air cooled versions. The latest adiabatic technology is gaining traction too. These systems spray water mist to cool the air before it reaches the condenser coils. Recent tests from HVAC labs in 2023 showed these setups can reduce peak electricity usage by roughly 20% in moderate climate zones.

Function and Working Principle of Air-Cooled Condensing Units

Air cooled condensing units work by moving heat from refrigerant into the surrounding air via those finned coils and those big axial fans we all know. When the compressed refrigerant gets into the condenser coil, the forced air takes away that latent heat stuff, making it change from gas back to liquid form. One major advantage here is these systems don't need any water at all. That makes them really good choices for places where water is scarce or where there are strict environmental rules about water usage. Take a standard 10 ton commercial unit for example. It can get rid of around 120 thousand BTUs per hour worth of heat while only using somewhere between 3 and 5 kilowatts for the fans. But watch out folks, when outside temps go past 95 degrees Fahrenheit (about 35 Celsius), the system starts losing efficiency pretty fast, maybe dropping anywhere from 8% to 12% depending on conditions.

Advantages and Limitations of Each Condenser Type in Different Environments

- Air-cooled: Low maintenance and installation costs (~40% cheaper than water-cooled) but 15-25% less efficient in high-temperature environments

- Water-cooled: 30-50% longer lifespan in corrosive industrial settings but require cooling towers and water treatment systems

- Evaporative: Deliver 45°F (7°C) lower discharge temperatures than air-cooled units in dry climates but increase water consumption by 500-800 gallons daily

- Adiabatic: Reduce energy costs by 18-22% in mixed climates but face scaling challenges in hard water areas

As outlined in the 2024 Industrial Condenser Analysis, selection hinges on balancing local climate, operational costs, and regulatory constraints. Pharmaceutical cold chains frequently opt for water-cooled systems for stable 24/7 operation, while supermarkets prioritize air-cooled units for easier maintenance and lower upfront costs.

Energy Efficiency, Operational Costs, and Long-Term Savings

Impact of Condenser Units on Energy Efficiency in Refrigeration Systems

Condensing units directly influence 30-50% of a refrigeration system's total energy consumption due to their role in heat rejection. Modern designs with variable-speed compressors and enhanced coil surfaces improve seasonal energy efficiency ratios (SEER) by up to 22% compared to fixed-speed models.

Cooling Capacity and Temperature Considerations Affecting Efficiency

| Factor | High-Efficiency Impact | Conventional Unit Impact |

|---|---|---|

| Ambient Temperature | Maintains COP* above 3.0 at 45°C | COP drops to 1.8 at 45°C |

| Part-Load Operation | 40% energy reduction at 50% load | 15% reduction at 50% load |

| Refrigerant Type | R513A enables 12% efficiency gain | R404A limits thermal transfer |

| *Coefficient of Performance |

Data-Driven Insights: Energy Savings From High-Efficiency Condensing Units

A 2023 DOE study of 200 commercial facilities found systems using AHRI-certified condensing units achieved annual energy savings of $8,400 per 100 kW cooling capacity. High-efficiency models reduced compressor runtime by 35% through improved heat exchange rates.

Controversy Analysis: Initial Cost vs. Long-Term Operational Savings

While premium condensing units cost 25-40% more upfront, their 10-year operational savings outweigh initial investments:

- Energy Costs: $62,000 saved per unit (average 400 kW system)

- Maintenance: 30% fewer service calls due to corrosion-resistant components

- Downtime: 57% reduction in unplanned outages (ASHRAE 2022 data)

This cost-benefit imbalance creates market friction, with 38% of buyers prioritizing upfront price despite lifecycle savings evidence.

Applications, Selection, and Maintenance of Condensing Units

Condensing units form the operational backbone of temperature-controlled environments, with 78% of food preservation facilities relying on them for critical storage according to the 2023 ASHRAE Industrial Refrigeration Report. These systems excel in three key domains:

- Cold Storage (-18°C to 4°C): Preventing spoilage in meat, dairy, and produce

- Commercial Refrigeration: Powering supermarket display cases with ±0.5°C precision

- Pharmaceutical Manufacturing: Maintaining 2-8°C chains for vaccine integrity

Factors Influencing Condensing Unit Selection

| Priority | Operational Impact | Cost Implication |

|---|---|---|

| Cooling Capacity | Undersized units cause 27% compressor strain | +15-20% upfront vs. 40% energy loss |

| Ambient Temperature | Air-cooled units lose 18% efficiency per 5°C above 35°C | Water-cooled alternatives cost 2.1x more |

| Energy Efficiency | SEER 14+ models reduce annual costs by 30-50% | ROI achieved in 2-3 years |

Recent case studies from HVAC innovators demonstrate that units with variable-speed compressors cut defrost cycles by 60% in humid environments.

Maintenance Best Practices

- Coil Cleaning: Bi-monthly rinsing prevents 80% of airflow-related failures

- Refrigerant Charge Checks: Annual verification maintains ±5% efficiency targets

- Condenser Fan Inspections: Vibration analysis identifies 92% of bearing issues early

Proactive maintenance extends system lifespan by 40% compared to reactive repair strategies, according to 2024 data from refrigeration engineers.

FAQ

What is a condensing unit used for?

A condensing unit is used in refrigeration systems to compress gas and turn it into liquid form, playing a critical role in the vapor compression cycle.

How does a condensing unit work?

It works by entering high-pressure refrigerant gas into condenser coils, where heat is absorbed and the refrigerant cools to transition to liquid, then flows to the expansion valve for pressure reduction.

What are the types of condensing units?

There are air-cooled, water-cooled, evaporative, and adiabatic condensing units, each offering different efficiency and operational benefits.

How does maintenance impact condensing unit performance?

Regular maintenance like coil cleaning and fan inspections improves performance and extends system lifespan by preventing issues like airflow-related failures.

Table of Contents

- The Role and Working Principle of Condensing Units in Refrigeration

- Core Components and Their Contribution to System Performance

- Types of Condensing Units and Their Application-Specific Advantages

- Energy Efficiency, Operational Costs, and Long-Term Savings

- Applications, Selection, and Maintenance of Condensing Units

- FAQ