Cold room panel, also known as insulated sandwich panels, is the essential building blocks of any cold storage facility. They form the insulated envelope that maintains a stable internal temperature, ensuring that the refrigeration system operates efficiently. A well-designed panel system determines the thermal performance, energy efficiency, and longevity of the cold room. Over the past few decades, technological advancements have transformed cold room panel from simple insulation sheets into highly engineered building materials with excellent structural, thermal, and hygienic properties.

1. Characteristics of Cold Room Panels

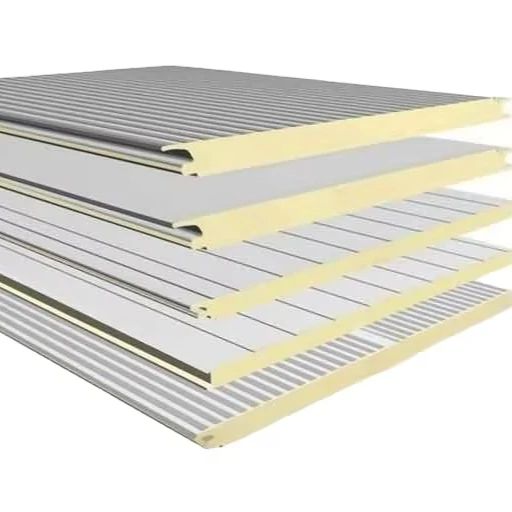

Sandwich Structure Design

A cold room panel is typically a three-layer sandwich structure consisting of an inner and outer metal skin with a rigid insulating core in between. The outer skins—usually made from pre-painted galvanized steel (PPGI), stainless steel, or aluminum—provide mechanical strength and protection against moisture and corrosion. The inner core, composed of materials such as polyurethane (PU), polyisocyanurate (PIR), expanded polystyrene (EPS), or rock wool, serves as the thermal barrier, minimizing heat transfer between the inside and outside of the cold room.

Excellent Thermal Insulation

Cold room panels are designed for superior thermal insulation. Polyurethane (PU) and PIR are especially popular due to their low thermal conductivity, typically between 0.018–0.024 W/m·K, which helps maintain internal temperatures ranging from +15°C to –40°C. The insulation layer prevents cold air loss, enhances energy efficiency, and ensures consistent temperature control throughout the storage space.

Airtightness and Moisture Resistance

The tongue-and-groove or cam-lock joint system used in cold room panels provides a perfect seal between panels, preventing air and moisture leakage. This airtight construction not only enhances cooling efficiency but also protects against condensation and frost buildup, ensuring the structural integrity of the panels over time.

Structural Strength and Stability

Cold room panels are self-supporting, rigid components capable of forming walls, ceilings, and floors. With steel skins laminated under high pressure, they achieve strong mechanical properties such as high bending and compressive strength. They can withstand internal pressure differences, external wind loads, and the mechanical stresses of stacking or assembly.

Hygienic and Easy-to-Clean Surfaces

Because cold rooms are used primarily for storing food and pharmaceuticals, hygiene is critical. The panel surfaces are designed to be smooth, non-porous, and corrosion-resistant, which prevents bacterial growth and allows easy cleaning. The use of food-grade coatings or stainless-steel cladding further enhances sanitary conditions and meets international hygiene standards such as HACCP and ISO 22000.

Fire Resistance and Safety

Modern cold room panels incorporate fire-resistant materials and additives to improve safety. PIR panels, in particular, offer excellent fire resistance and self-extinguishing properties. Rock wool panels are often used for fire-rated walls, providing non-combustible insulation that meets Class A fire resistance standards.

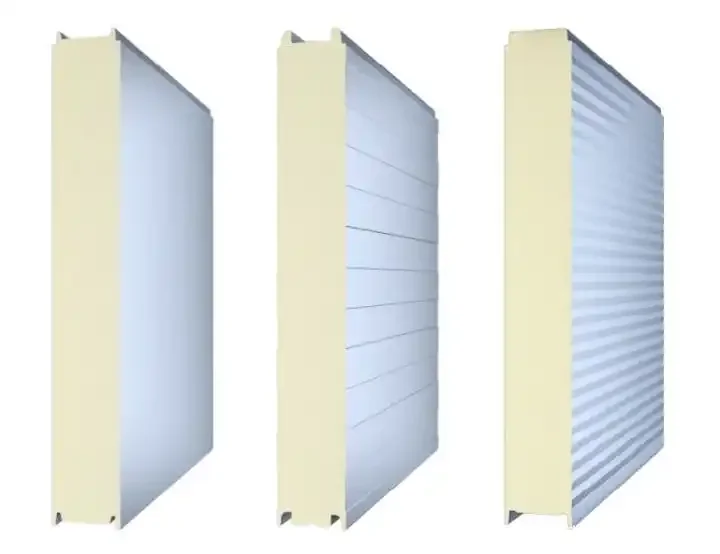

Modular and Customizable Design

Cold room panels are modular and prefabricated, allowing for flexible design configurations. Panels come in standardized widths (typically 960–1200 mm) and customizable lengths up to 12 meters, making installation quick and convenient. Their modular nature allows for easy disassembly, expansion, or relocation of cold rooms when necessary.

2. Advantages of Cold Room Panels

High Energy Efficiency

Cold room panels significantly reduce energy consumption by minimizing heat transfer. Their superior insulation performance lowers the workload of refrigeration equipment, resulting in reduced power usage and operational costs. The tight joints and moisture-resistant design further ensure minimal energy loss and better cooling efficiency.

Fast and Easy Installation

The modular design and integrated locking system make installation straightforward and efficient. Panels can be quickly assembled on-site with minimal labor and without the need for wet construction materials. This reduces construction time by up to 50% compared to conventional wall systems.

Durability and Longevity

The combination of high-strength metal surfaces and closed-cell insulation cores provides long-lasting durability. Cold room panels are resistant to corrosion, moisture absorption, pests, and physical damage, offering a service life of over 20–30 years with proper maintenance.

Lightweight yet Strong

Despite their excellent insulation and strength, cold room panels are lightweight, making them easy to transport and handle. Their low dead weight reduces the load on building structures and foundations, which is especially advantageous for modular or mobile cold storage units.

Hygienic and Aesthetic Appearance

The smooth, glossy surfaces of cold room panels not only enhance cleanliness but also provide a professional, modern appearance. The materials resist staining and discoloration, maintaining a clean look even after years of use. Optional anti-bacterial coatings further improve sanitary performance.

Environmental Sustainability

Many modern cold room panels use eco-friendly blowing agents such as cyclopentane instead of CFCs or HCFCs, reducing ozone depletion potential. Panels are also recyclable at the end of their service life, contributing to sustainable building practices and environmental responsibility.

3. Key Considerations During Manufacturing

The manufacturing process of cold room panels requires strict quality control to ensure thermal performance, structural integrity, and durability. Key factors to consider include:

Core Material Quality and Density

The insulation core must have uniform density and consistent foam structure. For PU and PIR panels, the ideal density is 38–45 kg/m³ to achieve optimal thermal and mechanical properties. Any voids, uneven foaming, or weak bonding between layers can significantly reduce panel performance.

Metal Surface Treatment

The outer and inner steel skins should undergo pre-treatment and coating processes such as galvanizing, chromate conversion, and polyester or PVDF coating. These coatings provide resistance to corrosion, humidity, and chemical exposure, especially in food storage environments.

Precision Lamination and Bonding

Panels are produced through continuous or discontinuous lamination under controlled pressure and temperature. The bonding between the insulation core and metal surfaces must be strong and uniform to prevent delamination. Automated production lines ensure dimensional accuracy and consistent product quality.

Joint and Locking System Design

Manufacturers must ensure tight interlocking between panels. The cam-lock or tongue-and-groove system should include durable PVC or EPDM gaskets to maintain an airtight seal. Proper design of joints minimizes heat bridges and ensures easy installation.

Dimensional Accuracy and Quality Testing

Panel thickness tolerance, straightness, and squareness are critical to assembly quality. Each panel should undergo thermal conductivity testing, dimensional inspection, adhesion testing, and fire resistance evaluation before dispatch.

Fire Safety Compliance

For panels used in high-risk environments, manufacturers must meet fire safety standards such as EN 13501-1 or FM Approvals Class 4880. This involves using fire-retardant foam formulations or non-combustible insulation like rock wool, depending on the project requirements.

Environmental Standards and Certification

Production should follow environmental and quality standards such as ISO 9001, ISO 14001, and CE marking. The use of eco-friendly materials and compliance with EU or ASHRAE regulations enhances the sustainability and credibility of the product.

4. Conclusion

Cold room panels are at the core of every efficient refrigeration facility, providing structural support, thermal insulation, and hygiene all in one system. Their sandwich construction, airtight joining system, and customizable modular design make them ideal for a wide range of temperature-controlled applications. When manufactured with precision and high-quality materials, cold room panels deliver exceptional energy efficiency, durability, and safety.

However, achieving optimal performance requires attention to detail in panel design, material selection, fire resistance, and assembly precision. Adhering to technical specifications and international standards ensures long-term reliability and energy savings.

ONLINE

ONLINE