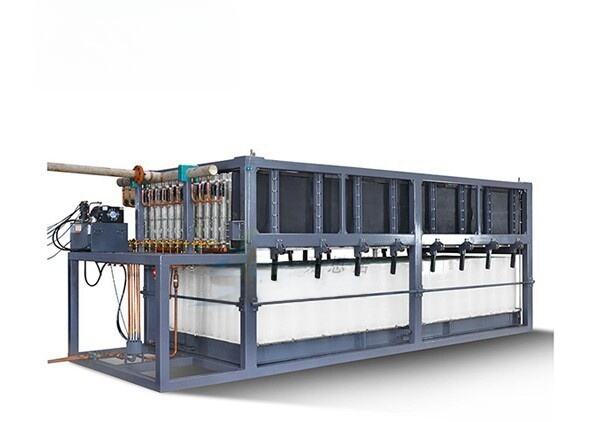

BH Building Co., LTD, an outstanding branch of Harbin Dongan Building Sheets Co., LTD, is a leading provider of energy saving ice block machine, integrating advanced refrigeration technology with energy-efficient design to minimize power consumption while maximizing ice production. Energy saving ice block machine is engineered to reduce operational costs, utilizing high-efficiency compressors, optimized heat exchange systems, and smart sensors that adjust cooling cycles based on ice demand, ensuring that energy is used only when necessary—this makes it an ideal choice for businesses across diverse cultural and geographical regions looking to lower their carbon footprint and utility bills. Our energy saving ice block machine does not compromise on performance; it produces high-quality ice blocks with consistent density and cooling capacity, suitable for preserving seafood, meat, and other perishables in markets, restaurants, and industrial facilities. We understand that different regions have varying energy costs and environmental regulations, so our energy saving ice block machine is designed to comply with international energy efficiency standards, with customizable settings to adapt to local power grids and usage patterns. The construction of energy saving ice block machine uses durable, heat-resistant materials that reduce energy loss, while the compact design ensures it fits into tight spaces without sacrificing efficiency. Our full-chain service covers energy saving ice block machine from selection to post-maintenance, including installation guidance to optimize energy use and regular check-ups to keep the machine running at peak efficiency. With years of international market experience, we ensure that energy saving ice block machine can be efficiently shipped and installed worldwide, providing a sustainable, cost-effective ice production solution for clients seeking both performance and energy savings.

ONLINE

ONLINE