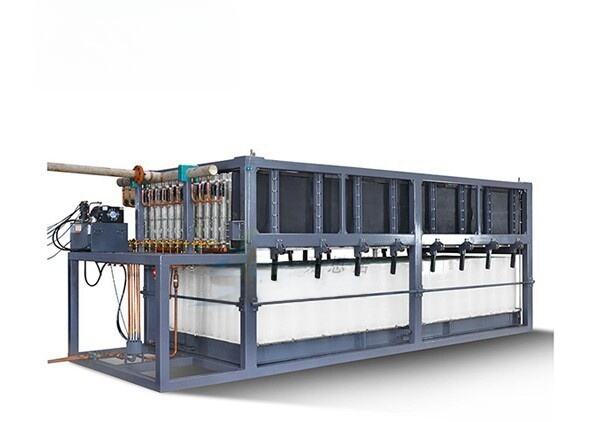

BH Building Co., LTD, an outstanding branch of Harbin Dongan Building Sheets Co., LTD, specializes in fast freezing ice block machine, engineered to produce ice blocks at an accelerated rate, meeting the urgent demands of markets, seafood processors, and industrial facilities where rapid ice production is critical. Fast freezing ice block machine utilizes advanced refrigeration technology, including high-power compressors, enhanced evaporator systems, and low-temperature refrigerants that accelerate the freezing process, allowing it to generate ice blocks in significantly less time than standard machines—this makes it ideal for businesses across diverse cultural regions that need to quickly replenish ice supplies during peak hours or after unexpected demand surges. Our fast freezing ice block machine maintains ice quality despite its speed; the ice blocks are dense, hard, and slow-melting, ensuring effective cooling for preserving perishables like fish, meat, and vegetables. We understand that different operations have varying ice size requirements, so our fast freezing ice block machine is customizable, producing ice blocks of different dimensions to fit specific storage containers and usage needs. The construction of fast freezing ice block machine is robust, with heat-resistant materials that withstand the stress of rapid temperature changes, and a cooling system designed to prevent overheating during extended fast-freezing cycles. Our full-chain service covers fast freezing ice block machine from selection to post-maintenance, including installation guidance to optimize freezing speed and regular maintenance to keep the machine operating at peak performance. With years of international market experience, we ensure that fast freezing ice block machine can be efficiently shipped and installed worldwide, providing a reliable, high-speed ice production solution for clients who need to balance speed, quality, and durability in their daily operations.

ONLINE

ONLINE