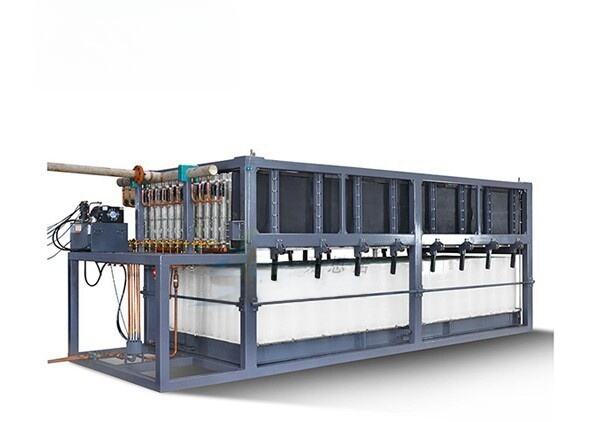

BH Building Co., LTD, an outstanding branch of Harbin Dongan Building Sheets Co., LTD, specializes in ice block machine with compact design, offering innovative solutions that combine space efficiency with high-performance ice production for diverse commercial and industrial needs. Ice block machine with compact design is engineered to fit into limited spaces, making it ideal for small-scale businesses, restaurants, and seafood markets where space is a premium, while still delivering consistent ice block output to meet daily demands. Our ice block machine with compact design integrates advanced refrigeration technology with a streamlined structure, ensuring efficient operation without compromising on ice quality—each ice block is formed with precision, maintaining the right hardness and clarity required for preserving perishables. We understand that clients from different cultural backgrounds have varying space constraints and usage patterns, so our ice block machine with compact design is customizable in terms of ice block size and production capacity, adapting to local market needs seamlessly. The compact design of the ice block machine does not sacrifice durability; we use high-quality materials for key components, ensuring long-term reliability and easy maintenance, which is crucial for businesses operating in busy environments. Our full-chain service covers ice block machine with compact design from selection to post-maintenance, including installation guidance to maximize space utilization and technical support to resolve any operational issues. With years of international market experience, we ensure that ice block machine with compact design complies with global safety standards and can be efficiently shipped and installed worldwide, making it a practical choice for clients seeking space-saving yet powerful ice production solutions.

ONLINE

ONLINE